Duplex Board and CCNB

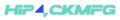

Duplex Board

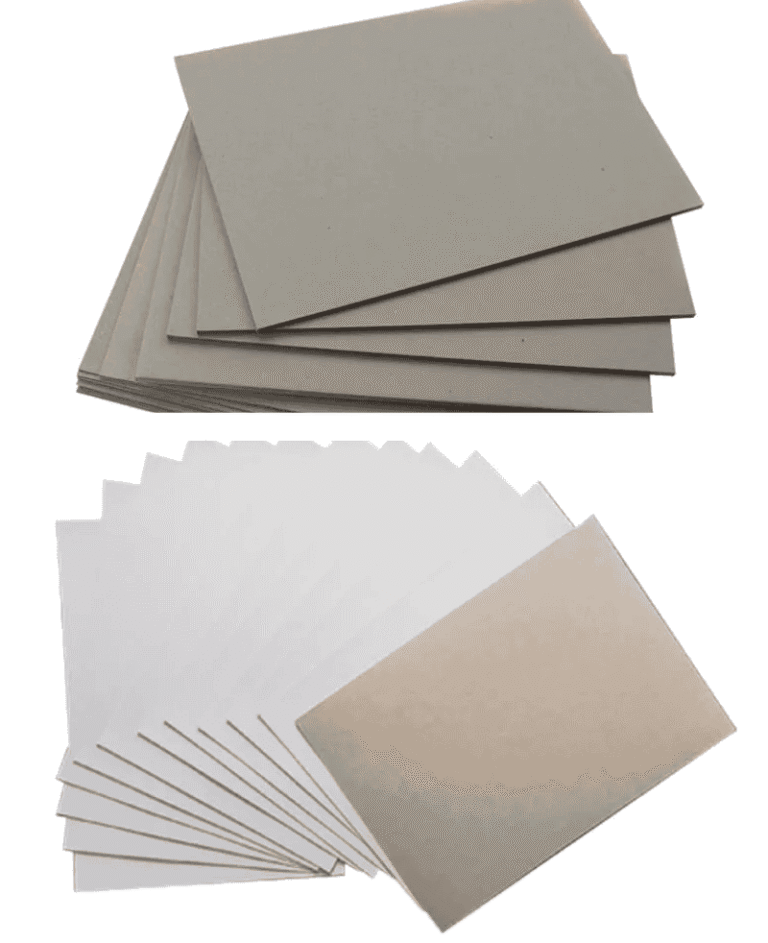

Duplex board, also known as grey board or white-lined chipboard, is a strong and versatile packaging material composed of two layers of pulp. The outer layer can be coated for enhanced print quality and barrier properties, while the inner layer is typically made from recycled material. Available in a range of thicknesses and finishes, duplex board is used for both luxury rigid boxes and affordable folding cartons.

Key Features:

- Excellent stiffness and durability for rigid packaging

- Available with grey or white back, coated or uncoated

- Suitable for high-end print finishing (foil, embossing, etc.)

- Widely used in electronics, cosmetics, apparel, and food packaging

- FSC-certified options available

CCNB (Clay Coated Newsback)

CCNB is a duplex paperboard made from recycled paper pulp. Its front side is coated with white kaolin clay, creating a smooth, bright surface ideal for printing crisp designs and vibrant colors. The back side is typically uncoated, with a natural brown or grey kraft appearance and a slightly rough texture.

Key Features:

Contains up to 90% recycled content

Excellent printability on the coated side

Cost-effective and widely used for everyday packaging

100% recyclable and eco-friendly

Common for food, shoes, folding cartons, and mailers

CCNB vs Duplex Board: Differences & Selection Guide

Surface & Structure

CCNB: Clay-coated on the front, rough kraft back. Best for one-sided printing.

Duplex Board: Can be clay-coated on one or both sides; available with grey or white back. More choices for double-sided printing and luxury finishing.

Strength & Thickness

CCNB: Available from 250-527gsm (12-28pt), commonly used for medium-duty packaging.

Duplex Board: Wide range from 250gsm up to 1800gsm (0.3-3mm), suitable for both folding cartons and rigid boxes.

Printing & Appearance

CCNB: Excellent print surface for sharp, colorful graphics. Backside not suitable for display.

Duplex Board: Offers premium print quality, with options for glossy or matte finishes on both sides. Great for packaging where both sides are visible.

Environmental Attributes

Both: Highly recyclable, made from recycled content, can be FSC certified.

CCNB: Higher recycled content, best for brands seeking cost-effective sustainability.

Duplex Board: Stronger, more versatile, supports luxury packaging with eco-credentials.

Cost

CCNB: Lower cost, ideal for mass-market or budget-friendly packaging.

Duplex Board: Slightly higher, but adds value through luxury appearance and feel.

| Feature | CCNB (Clay Coated Newsback) | Duplex Board |

|---|---|---|

| Structure | White kaolin clay-coated front, grey/brown kraft back | Two layers: coated or uncoated (grey/white back available) |

| Main Material | Recycled pulp, up to 90% | Mix of recycled & chemical pulp |

| Printability | Excellent on coated side | Good (coated better for print) |

| Back Side | Rough, uncoated, natural color | Grey or white, can be coated |

| Eco-Friendly | Highly recyclable | Highly recyclable, FSC options |

| Cost | Very cost-effective | Cost-effective, slightly pricier |

| Common Uses | Shoe boxes, food boxes, mailers, folding cartons | Rigid boxes, folding cartons, book covers, food packaging |

| Thickness Range | 250-527gsm (12-28pt) | 250-1800gsm (0.3-3mm) |

| FSC Certified? | Optional | Yes, available |

Note: Need help choosing? Contact our experts or use our Material Selector below!

When to Choose CCNB?

- You need cost-effective packaging for daily products (e.g. shoes, food, retail).

- Single-side printing is sufficient.

- Environmental sustainability is a priority.

When to Choose Duplex Board?

- You need luxury rigid boxes, high-end folding cartons, or premium print finishes.

- Two-sided printing or special coatings required.

- Maximum rigidity and durability are essential.

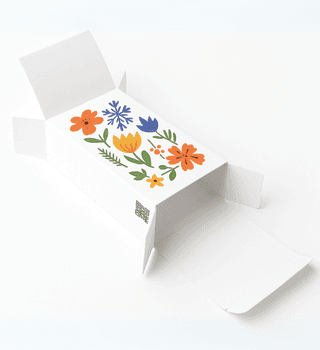

Food Packaging

Mailers & Shipping Boxes

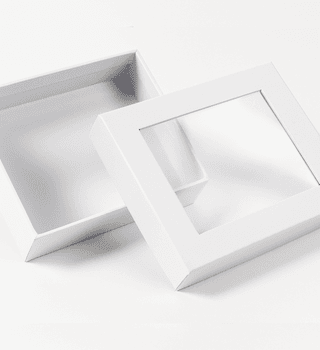

Rigid Inserts

Natural Brown Kraft Paperboard Specification Table

| Thickness (pt) | Grammage (gsm) | Caliper (mm) | Typical Use |

|---|---|---|---|

| 12 pt | 250 gsm | 0.30 | Small bags, folding cartons |

| 14 pt | 275 gsm | 0.36 | Takeout boxes, cups |

| 16 pt | 300 gsm | 0.40 | Heavier bags, folding cartons |

| 18 pt | 350 gsm | 0.46 | Gift boxes, rigid packaging |

| 24 pt | 400 gsm | 0.61 | Heavy-duty boxes |

| 28 pt | 527 gsm | 0.71 | Extra rigid boxes, mailers |

| 36 pt+ | 700 gsm+ | 0.90+ | Luxury rigid boxes, book covers |

| Up to 3mm | 1800 gsm | 3.00 | Specialty rigid packaging |

Note: Need help matching your product to the right thickness? Talk to our experts!

Not sure which material or option to choose?

- Expert advice on choosing the best material and structure to meet your needs

- Professional guidance from engineers and designers on building the best packaging experience

- Anytime support with full-cycle project management and proactive updates

FAQ

Basis Weight: Measured in Grams per Square Meter (GSM), this fundamental specification denotes the board’s weight per unit area. Typical ranges for duplex board fall between 200 GSM and 500 GSM, with higher GSM values indicating increased thickness and rigidity.

Coating: Duplex board often features a coating on one side, typically composed of clay or similar additives. This coating enhances the surface’s gloss, smoothness, and printability, leading to superior aesthetic and functional outcomes for printed graphics.

Brightness: This metric quantifies the percentage of light reflected by the board’s surface, particularly on the coated side. Measured on the ISO scale, higher brightness levels generally correlate with improved print quality and vibrancy.

Ply: Duplex board is constructed from multiple layers, or plies, of pulp that are laminated during manufacturing. The number of plies directly influences the board’s overall strength, stiffness, and structural integrity.

Smoothness: Essential for optimal print reproduction, the smoothness of the coated surface is typically quantified in Sheffield Units (SU). Higher SU values denote a smoother surface, which is critical for high-resolution printing.

Folding Endurance: This specification assesses the board’s ability to withstand repeated creasing and folding without compromising its structural integrity. It is a vital characteristic for packaging applications involving folding or forming, with higher values indicating greater durability.

Bursting Strength: This measures the board’s resistance to rupture when subjected to pressure or force. Expressed in units of pressure, bursting strength is a critical parameter for packaging that must endure external stresses during handling and transportation.

Coating Weight: The amount of coating applied to the board’s surface is also measured in GSM. A greater coating weight generally contributes to enhanced print fidelity and surface finish, though it can also influence material cost and other physical properties.

Caliper: Also known as thickness, caliper is measured in micrometers ($\mu$m) or mils. This dimension varies depending on the board’s grade and basis weight and is crucial for determining its overall bulk and suitability for specific machinery.

Yes, we have an in-house design team to assist with dielines, artwork, and structure suggestions to achieve the best results.