Ultimate Guide to

Gift-Box Packaging

Learn about materials, printing techniques, inks, finishes, structural features,

and bag handles to create sustainable, cost-effective, and visually stunning packaging solutions.

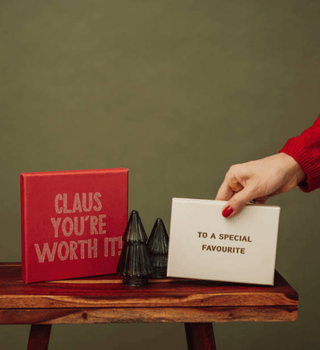

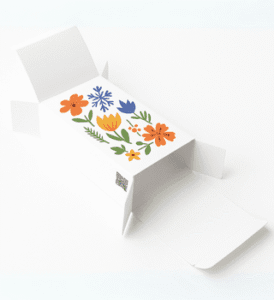

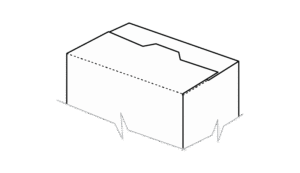

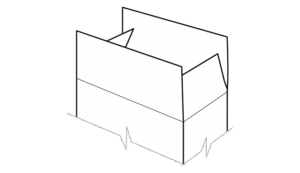

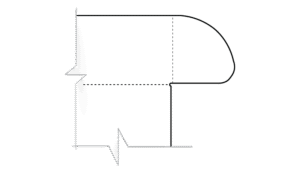

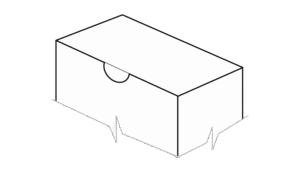

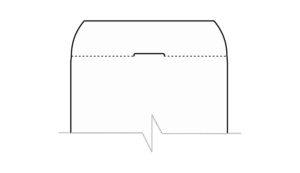

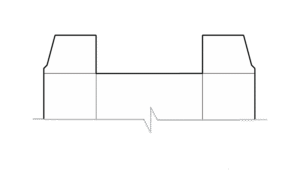

Packaging Styles:

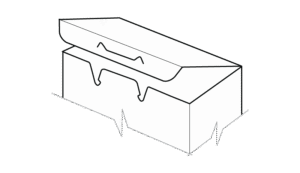

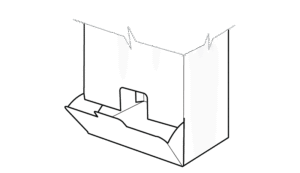

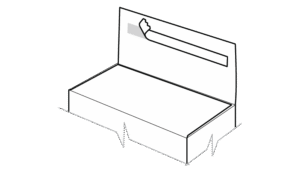

Box Structural Features:

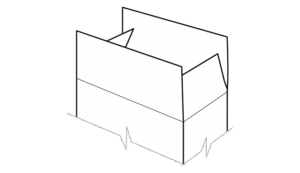

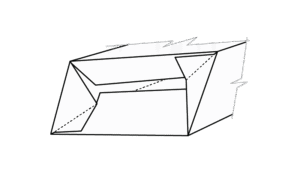

Top Closures

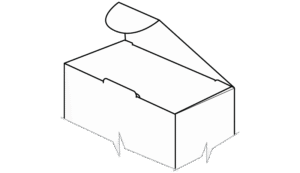

- Friction-Fit Tuck: Quick assembly for retail (e.g., chocolatiers).

- Slit-Lock Tuck: Secure, survives shipping.

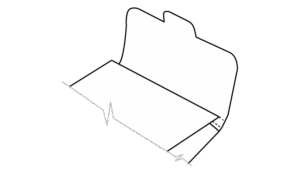

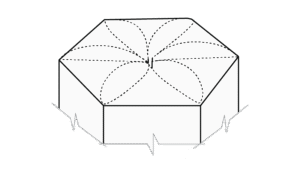

- Flower Petal: Theatrical opening for boutique gifts.

- Gable Handle: Portable, no extra bag needed.

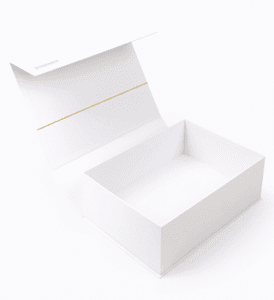

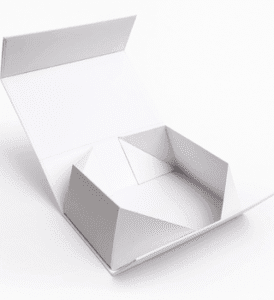

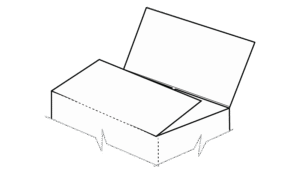

- Magnetic Lid: Reusable luxury option (rigid boxes).

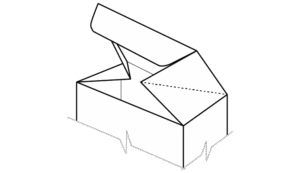

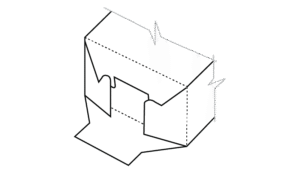

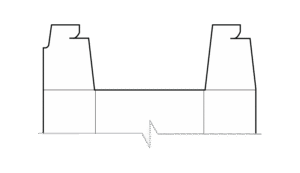

Bottom Closures

- Snap-Lock/1-2-3 Bottom: Self-locking, tape-free.

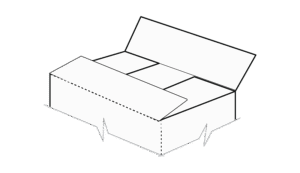

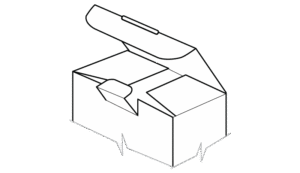

- Auto-Bottom: Pre-glued, instant setup for e-commerce.

- Full Overlap: Heavy-duty, stackable strength.

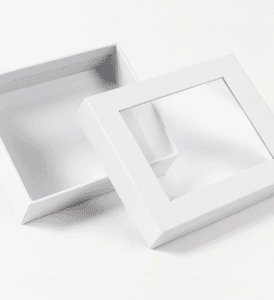

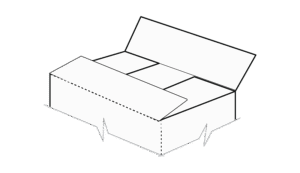

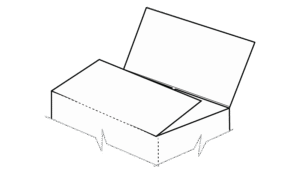

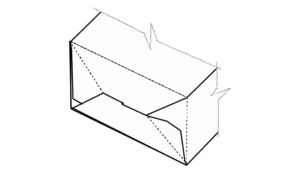

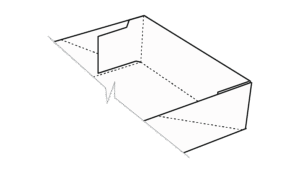

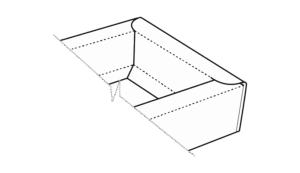

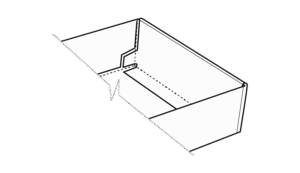

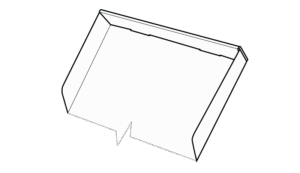

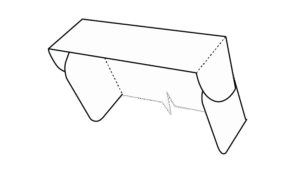

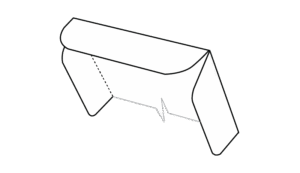

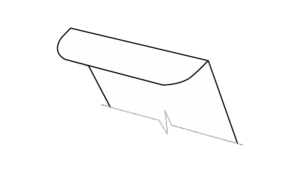

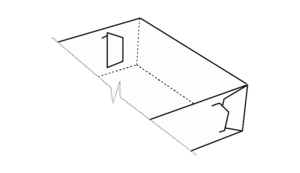

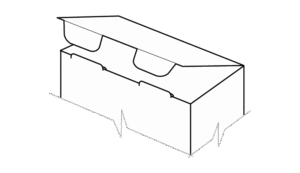

Trays & Lids

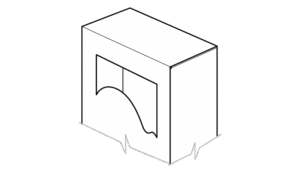

- Roll End Tray: Material-efficient, optional windows.

- Pinch-Lock Tray: Triple-wall strength for gourmet items.

- Four-Corner Tray: Flat shipping, fast assembly.

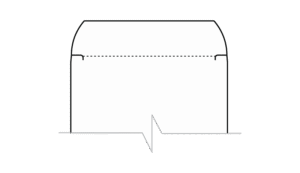

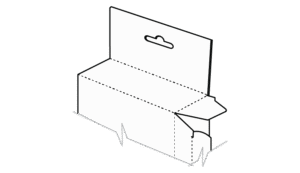

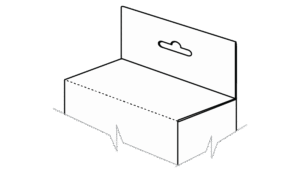

Miscellaneous Add-ons

Enhance functionality with these features:

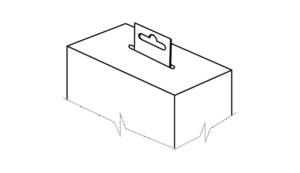

- Dust flaps, thumb cut-outs, tear strips, child-resistant locks, adhesive strips, perforated dispensers, window cut-outs, hang tabs, anchor locks, corner punch-outs.

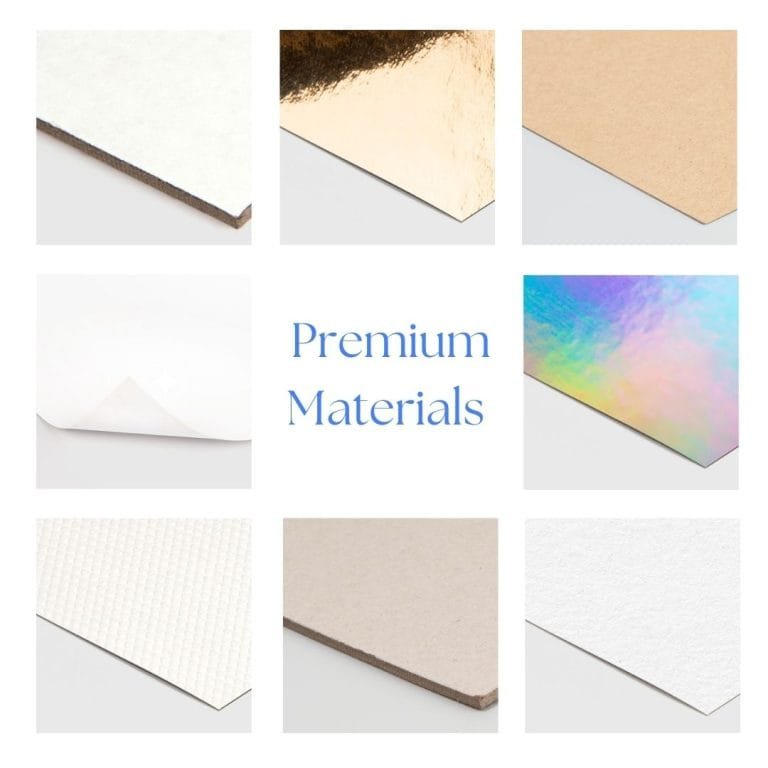

Materials:

Paperboards for Gift Boxes

| Feature | SBS C1S | SBS C2S |

|---|---|---|

| Thickness | 0.30–0.50 mm / 250–350 gsm | 0.35–0.60 mm / 300–400 gsm |

| Printability | High (coated side) | Very High (both sides) |

| Rigidity | Medium | Medium-High |

| Sustainability | Recyclable | Recyclable | Typical Uses | Cosmetic cartons, mailers | Luxury gift boxes |

| Cost | ★★ | ★★★ |

Note: Advantages: Easy to print, recyclable, cost-effective. Disadvantages: Limited durability for heavy items.

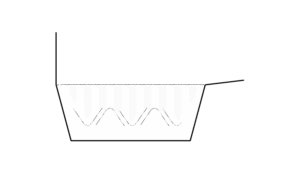

Corrugated Boards: Triple-Layer Strength

- Natural Kraft (E/F Flute): Rustic aesthetic, low ink rub-off. Best for: Presentation boxes, eco-friendly packaging.

- Oyster White: Lightly coated for vintage prints. Best for: Retro-style gift boxes.

- Kemi/Bleached White: Bright finish for photo-realistic graphics. Best for: High-end retail packaging.

Advantages: Durable, protective, recyclable. Disadvantages: Bulkier than paperboards, higher cost.

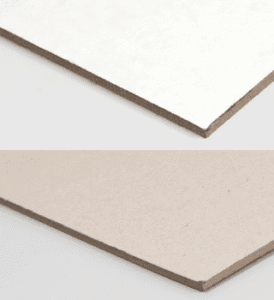

Rigid Chipboards: Luxury Foundations

- Grey Chip (1.2–3 mm): Affordable luxury option for jewelry and electronics packaging.

- White/Duplex Chip: White outer layer allows direct printing, eliminating the need for wrapping.

Advantages: High rigidity, luxurious appeal. Disadvantages: Higher cost, less eco-friendly.

Plastics: Transparency and Protection

| Feature | PET | PVC |

|---|---|---|

| Clarity | Crystal clear | High clarity |

| Temp Resistance | Up to 60°C | Up to 70°C |

| Food-Safe | Yes | No |

| Uses | Windows, blister fronts | Display packaging |

Note: Advantages: Transparent, durable. Disadvantages: Less sustainable, not always recyclable.

Foams and Molded Pulp: Protective Options

- Foams: EVA (luxury inserts), EPE (recyclable void-fill), PU (soft cushions).

- Molded Pulp: Dry-press (egg-crate style), wet-press (smooth finish), secondary-processed (dyed/coated).

Advantages: Excellent protection, eco-friendly (pulp). Disadvantages: Foams less sustainable, pulp less premium.

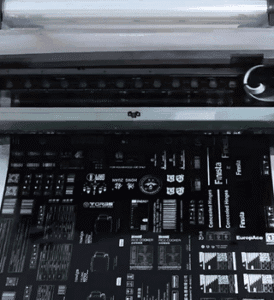

Print Methods:

| Method | Offset Lithography | Flexography | Digital Printing |

|---|---|---|---|

| MOQ & Speed | 1,000+ / Medium | 500+ / High | 1+ / Fast |

| Color Fidelity | ★★★★★ | ★★★ | ★★★★★ |

| Best For | Photo-realistic, Pantone colors | Simple designs, kraft paper | Small runs, personalization |

| Cost | $$ | $ | $$$ |

Note: Advantages: Offset offers superior quality, flexography is cost-effective, digital is flexible. Disadvantages: Offset has high setup costs, flexography lacks detail, digital is expensive per unit.

Inks:

- Water-Based: Odorless, kid-safe, fast-drying on paper. Best for: Eco-friendly packaging.

- Soy/Vegetable: 20% higher color gamut than petroleum inks. Best for: Vibrant designs.

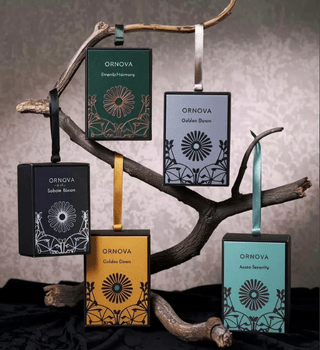

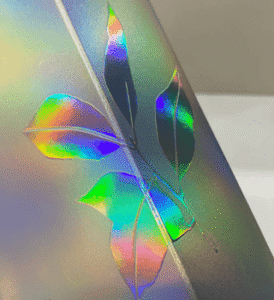

- Pantone Solid/Metallic: Consistent brand colors, metallic sheen. Best for: Premium branding.

- Fluorescent: Eye-catching POP displays (needs UV inhibitors). Best for: Retail standout.

- Oil-Based: Deep blacks on uncoated stocks. Best for: Traditional offset printing.

Advantages: Diverse options for aesthetics and safety. Disadvantages: Some require special coatings, higher costs for specialty inks. Pro-Tip: Use ISO 22000-compliant inks for food-safe packaging.

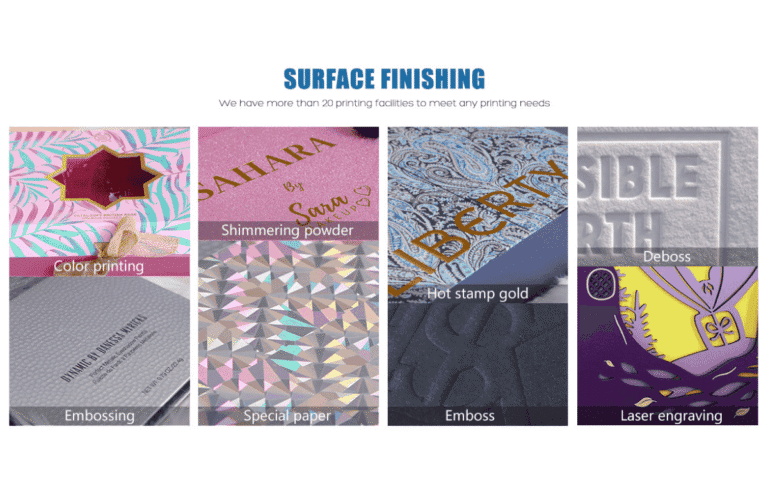

Finishes:

Coatings

| Type | Aqueous (AQ) | UV Coating |

|---|---|---|

| Feel | Satin-smooth | Glossy |

| Protection | Scratch & moisture ★★ | High ★★★ |

| Eco Note | Water-based, recyclable | Less eco-friendly |

Note: Need help choosing? Contact our experts or use our Material Selector below!

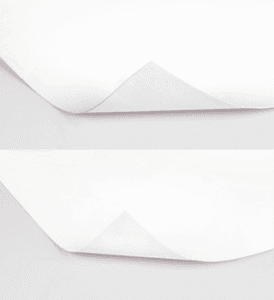

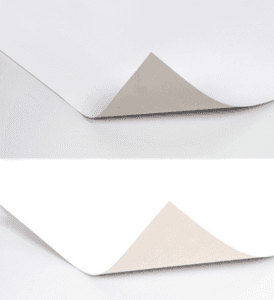

Laminations

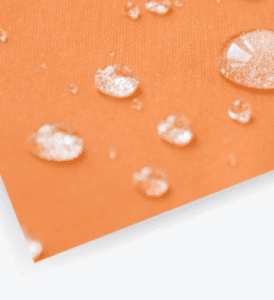

- BOPP Gloss/Matte: Vibrant, poster-like finish; requires delamination for recycling.

- Anti-Scratch BOPP: Durable, ideal for mobile phone boxes.

- Soft-Touch/Silk: Velvety 50 µ finish; higher MOQ (≥500 pcs).

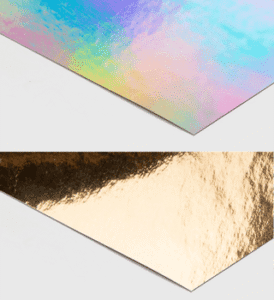

Special Effects

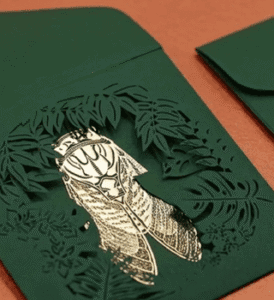

| Effect | Hot Foil | Embossing |

|---|---|---|

| Adds | Metallic mirror | Tactile texture |

| MOQ | 300+ | 500+ |

| Notes | Requires metal die; great for rigid lids | Enhances logos, patterns |

Note: Advantages: Elevates design, adds protection. Disadvantages: Increases cost, some not recyclable.

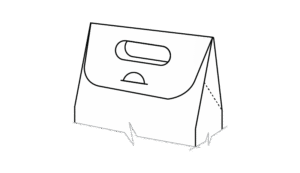

Bag Handles:

Paperboards for Gift Boxes

| Handle Style | Polypropylene Rope | Twisted Paper | Satin Ribbon |

|---|---|---|---|

| Strength | 10 kg | 5 kg | 3 kg |

| Touch & Look | Slick, modern | Rustic, soft | Elegant, smooth |

| MOQ | 1,000 | 500 | 1,000 |

| Eco | ♻️ | ♻️ Biodegradable | × |

Note: Advantages: Enhances portability, style. Disadvantages: Some less durable, higher MOQs.

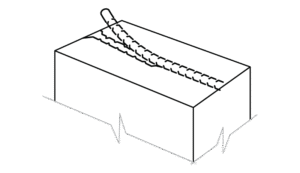

Polypropylene Rope:

Polypropylene rope handles are made from synthetic fibers, renowned for their strength and durability. Lightweight and resistant to water, chemicals, and UV rays, they are ideal for bags used in diverse environments, such as reusable shopping totes or outdoor carriers, offering a modern and practical design.

Nylon Rope:

Nylon rope handles, crafted from synthetic polyamide fibers, provide high tensile strength and elasticity. Their ability to absorb shock and resist abrasion makes them perfect for heavy-duty bags like travel or work carriers, combining functionality with a sleek, professional appearance.

Cotton Rope:

Cotton rope handles, made from natural fibers, offer a soft, comfortable grip. Biodegradable and eco-friendly, they suit lighter loads in casual tote bags or eco-conscious packaging, adding a warm, rustic aesthetic despite lower strength compared to synthetic options.

Grosgrain Ribbon:

Grosgrain ribbon handles, woven from ribbed fabric, blend durability with decorative appeal. Their unique texture enhances bags like boutique shopping or gift carriers, providing an elegant, refined look while maintaining moderate strength and resistance to water and UV rays.

Die-cut:

Die-cut handles are cut directly into the bag’s material, typically paper or plastic, offering a cost-effective, minimalist solution. Suitable for lightweight bags like shopping or merchandise carriers, they can be reinforced for added strength and provide a seamless, modern design.

Twisted Paper Handles:

Twisted paper handles, formed from twisted kraft paper, are lightweight, recyclable, and eco-friendly. Best for light to medium-weight bags such as retail or gift carriers, they offer a simple, natural look that aligns with sustainable branding.

Flat paper handles:

Flat paper handles, made from kraft paper strips, are economical and eco-friendly. Easy to produce and recyclable, they suit lightweight bags like food or small retail carriers, delivering a basic, functional style that supports sustainability goals.

Quick Decision Guides

Simplify your choices with these tailored recommendations for Gift-Box Packaging

1

Photo-quality luxury reusable box?

Rigid chipboard with SBS C2S, soft-touch lamination, hot foil.

Shipping fragile glassware?

E-flute Kemi White mailer, auto-bottom, EVA insert.

2

Eco-friendly tea hamper?

Natural kraft paperboard, water-based ink, twisted paper handle.

Not sure which material or option to choose?

- Expert advice on choosing the best material and structure to meet your needs

- Professional guidance from engineers and designers on building the best packaging experience

- Anytime support with full-cycle project management and proactive updates