White Kraft Paperboard

White Kraft Paperboard is a premium-grade packaging material, crafted from 100% virgin bleached wood pulp. Renowned for its pristine white appearance, durability, and exceptional printability, it delivers high-end visual appeal and practical strength for various packaging applications.

- Colors Available: Pure bright white and creamy white

- Grades Available:

- > Standard (for general packaging)

- > Food-grade (with wax or PE coating)

- > Moisture-resistant (coated)

- > High-strength & tear-resistant (thicker gsm grades)

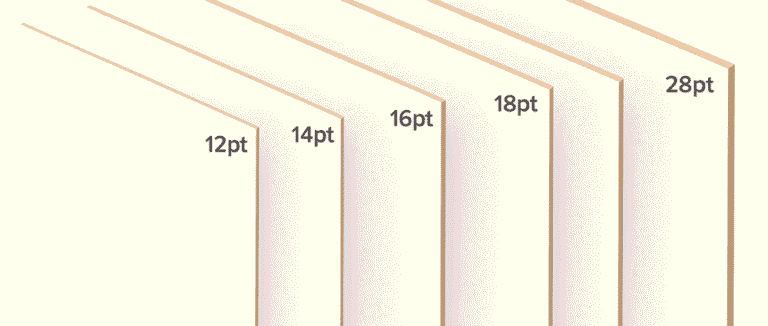

Cardboard Thickness

Best White Kraft Paperboard Thickness for Different Boxes

Use this clear, practical table to instantly know the recommended thickness (pt) of white kraft paperboard for your packaging:

| Type of Packaging | Recommended Thickness | Why This Thickness? |

|---|---|---|

| 📦 Folding Carton Boxes | 14–18 pt (270–350gsm) | Lightweight, strong, and easy to fold. Ideal for retail, cosmetics, and general product boxes. |

| 🗂️ Folding Carton Inserts | 14–16 pt (270–300gsm) | Thin yet sturdy. Perfect for internal supports and partitions within packaging boxes. |

| 🎁 Rigid Boxes | 18–28 pt (350–527gsm) | Strong, durable, luxurious feel. Perfect for premium packaging, electronics, cosmetics, and high-end gift boxes. |

| 📏 Rigid Inserts | 16–24 pt (300–400gsm) | Strong internal support structures for rigid boxes to keep products secure. |

| 🥡 Rigid Tubes | 18–28 pt (350–527gsm) | Excellent rigidity and durability. Ideal for cylindrical packaging, gift tubes, wine, or spirits. |

Note: "pt" stands for points; a higher number means thicker and stronger paperboard.

How to Select the Right White Kraft Paperboard

- Step 1: Define application (food, luxury, retail, heavy-duty, printing)

- Step 2: Choose basis weight and thickness according to packaging needs

- Step 3: Decide on performance (food-safe, waterproof, flame-retardant)

- Step 4: Select finishing (lamination, embossing, custom printing)

- Step 5: Request a quote/sample based on your specifications

How Do I Choose the Right Thickness?

Think about your product and how the box will be used:

Go for 14–18 pt folding carton boxes.

Choose 18–28 pt rigid boxes for maximum protection and brand value.

14–16 pt inserts for folding cartons or 16–24 pt inserts for rigid boxes.

Choosing the right material sets the tone for your gift box, impacting both its durability and perceived value. We offer a diverse selection to meet every need.

- Thickness used: 12 pt (225gsm)

- Finishing: embossing with spot UV

- Result: Cost-effective, eye-catching packaging suitable for shelf display.

- Thickness used: 20 pt (400gsm)

- Finishing: Matte lamination + debossing

- Result: Premium look, increased brand appeal.

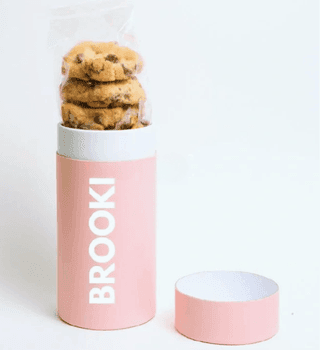

- Thickness used: 24 pt (450gsm)

- Special Coating: Food-grade wax coating

- Result: Beautiful, protective packaging, ensuring product freshness.

Not sure which material or option to choose?

No worries! We understand that getting the perfect custom packaging that meets your needs can be pretty tricky.

- Expert advice on choosing the best material and structure to meet your needs

- Professional guidance from engineers and designers on building the best packaging experience

- Anytime support with full-cycle project management and proactive updates

FAQ

Both are made from bleached pulp and offer high whiteness and printability. SBS is often used in high-end packaging and may offer slightly higher brightness, while white kraft paperboard is more versatile in finishing options and can be more cost-effective.

Yes, our food-grade lines comply with FDA 21 CFR 176.170, EU Regulation EC 1935/2004, and are ISEGA certified.

Absolutely! We offer full customization from 250 gsm up to 2,200 gsm, various coatings (wax, matte, gloss, biodegradable), and any size or die-cut shape.

Absolutely! Its superior whiteness and smoothness allow for sharp, vibrant printing and special finishes, enhancing the perceived luxury of your products.

We offer various materials such as paperboard, greyboard, kraft, art paper, and specialty papers. Finishes include matte/glossy lamination, foil stamping, embossing, UV coating, and more.

Yes, we have an in-house design team to assist with dielines, artwork, and structure suggestions to achieve the best results.