How to Elevate Your Brand Packaging with Custom Luxury Gift Boxes

When customers unbox your product, the first impression comes from your packaging. A flimsy or generic carton can squander months of design work, while a thoughtfully crafted rigid box can protect your product, amplify perceived value, and drive brand loyalty. In this guide, you’ll learn how to leverage custom luxury gift boxes [1]—from concept to shipment—to dazzle shoppers and differentiate your brand.

Why Luxury Packaging Matters

- Transforms perception: 72% of consumers say packaging design influences purchase decisions.

- Differentiates on the shelf: Premium finishes help your SKU outshine competitors.

- Builds loyalty: Branded unboxing can increase repeat purchases by up to 40%.

Keyword focus: luxury gift box manufacturers, custom box manufacturers, luxury packaging supplier [2]

How Rigid Boxes Protect & Impress

| Benefit | How It Works | Result |

|---|---|---|

| Shock resistance | Thick paperboard walls (≥1.5 mm) absorb impact | Fewer breakages in transit |

| Brand storytelling | Velvet inlays, foil logos, magnetic lids | Elevated unboxing experience |

| Reusability | Durable hinges keep shape after opening | Extended brand exposure |

Related search terms: rigid box manufacturers, luxury rigid box manufacturer, custom rigid box manufacturer

Top 3 Luxury Gift Box Styles

1. Two‑Piece Setup Boxes

Sleek base + lid format ideal for cosmetics, perfume, tech, and jewelry.

2. Magnetic Closure Foldables

Ships flat, pops into shape. Perfect for bulk orders where freight savings matter.

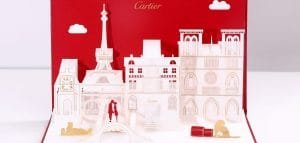

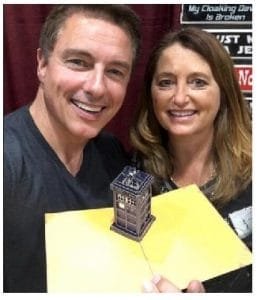

3. 3D Pop‑Up Presentation Boxes

Interactive mechanisms reveal products in layers—great for PR kits and limited editions.

Choosing the Right Manufacturer

- Capabilities – Can they emboss, spot‑UV, or engineer 3D pop‑ups?

- Certifications – FSC, ISO9001, or Sedex for ethical sourcing.

- MOQ & Lead Time – Typical custom gift box manufacturers start at 500 pcs with 15‑30 day production.

- Geography – Working with China gift box manufacturers can lower unit cost while maintaining quality; request samples and QC reports.

Packaging Project Timeline

![]()

| Phase | Week 0‑2 | Week 3‑4 | Week 5‑8 | Week 9‑10 |

|---|---|---|---|---|

| Define Specs | Size, artwork, inserts | – | – | – |

| Prototype | Receive white sample | Revise dieline | Approve pre‑production sample | – |

| Mass Production | – | Material prep | Printing & lamination | Assembly & QC |

| Shipping | – | – | Booking freight | Dispatch |

Keeping Quality in Check

- Fit Test: Product shouldn’t rattle or bulge.

- Edge Reinforcement: Glue corners, add internal braces for heavy items.

- Random Inspection: Check 2% of cartons on arrival for color, glue, and print accuracy.

Success Stories

A U.S. fragrance startup switched to a matte‑black rigid box with gold foil stamping—and saw 28% sales growth in six months, plus dozens of unboxing videos on TikTok.

FAQs

Q1. What’s the minimum order quantity?

Most cardboard gift box manufacturers[3] require ≥ 500 units; larger runs unlock better bulk pricing.

Q2. Can I get eco‑friendly rigid boxes?

Yes. Ask your luxury packaging supplier[2] for recycled greyboard and soy‑ink options.

Q3. How long does shipping from China take?

Express air: 5‑7 days; sea freight to U.S./EU: 20‑35 days, depending on port congestion.

Conclusion

Investing in custom luxury gift boxes[1] isn’t just about aesthetics—it’s about safeguarding your product, raising perceived value, and creating an unforgettable brand moment. Ready to outshine competitors? Partner with a trusted gift box manufacturer today and let your packaging do the talking.

Need help? Contact our team for free dieline templates and a fast quote on premium rigid boxes.