Packing Tape: Everything You Need to Know

When it comes to packaging, the right tape can make all the difference. Let me walk you through everything you need to know about packing tape to ensure your shipments are secure and professional.

Packing tape is essential for securing packages during transit. Choosing the right tape involves understanding its adhesive properties, thickness, and overall quality. High-quality packing tape ensures your products arrive safely, maintains your brand’s reputation, and enhances the unboxing experience for your customers.

Let’s dive into the details of selecting the perfect packing tape for your needs.

How Does the Adhesive on Packaging Tape Work?

Ever wondered what makes packing tape stick so well? Let’s explore the magic behind the adhesive.

The adhesive on packing tape is a carefully formulated glue that bonds the tape to surfaces. Typically, it’s a pressure-sensitive adhesive (PSA) that activates when pressure is applied, ensuring a strong and lasting hold.

Understanding the Adhesive Composition

The adhesive’s effectiveness is a result of its composition and the materials used in the tape. High-quality tapes use advanced adhesives that provide durability and resistance to environmental factors like temperature and moisture.

Key Components of Packing Tape Adhesive

| Component | Purpose |

|---|---|

| Pressure-Sensitive Adhesive1 (PSA) | Ensures strong bond with minimal effort |

| Tackifiers2 | Enhance stickiness and bond strength |

| Plasticizers3 | Improve flexibility and prevent brittleness |

| Fillers | Add volume and reduce costs |

By balancing these components, manufacturers create adhesives that perform reliably under various conditions, making your packaging secure.

What Determines the Color of Packing Tape?

Have you noticed packing tapes come in different colors? Here’s why color matters and what it signifies.

The color of packing tape is primarily influenced by the film4 and adhesive5 used in its production. While the film is often transparent, the adhesive can range from orange to beige. High-quality tapes tend to have a light yellow or white hue, indicating purity and minimal impurities.

The Significance of Tape Color

- Transparency6: Allows visibility of package contents and branding.

- Adhesive Quality: Lighter colors usually mean higher-quality adhesives.

- Aesthetic Appeal: Enhances the overall look of the package.

- Color Significance7: Reflects branding and psychological effects in packaging design.

Choosing the right color not only affects functionality but also the visual appeal of your packaging.

How Can You Assess the Quality of Packing Tape?

Ensuring you have high-quality packing tape is crucial for secure packaging. Here are some practical tips to evaluate tape quality effectively.

Quality packing tape should exhibit strong tension and stickiness. By manually testing the tape’s tension and adhesive strength, you can determine its reliability. Additionally, checking the tape’s thickness and the tightness of its wrapping provides insights into its overall quality.

Practical Testing Methods

- Color Inspection8: Look for light yellow or white tones.

- Scent Check9: High-quality tapes should have a neutral or mild smell.

- Tension Test10: Pull the tape to assess its strength.

- Thickness Measurement11: Opt for tapes around 50u for balance.

- Wrapping Tightness12: Ensure the tape is free from bubbles and impurities.

These steps help you select a tape that meets your packaging needs without compromising on quality.

Why is Tape Thickness Important in Packaging?

The thickness of packing tape plays a vital role in its performance and durability. Let’s break down why selecting the right thickness is essential.

Tape thickness, measured in microns (u), affects both the strength and length of the tape. Thicker tapes (around 60u) offer greater durability but are shorter in length, while thinner tapes (around 40u) are longer but more prone to breaking. A 50u tape strikes a perfect balance, providing sufficient strength without sacrificing length.

Balancing Thickness and Length

| Thickness (u) | Pros | Cons |

|---|---|---|

| 40u | Longer length, flexible | Less durable, easy to tear |

| 50u | Balanced strength and length | – |

| 60u | Highly durable, strong hold | Shorter length |

Choosing the appropriate thickness ensures your packaging is secure without unnecessary excess or vulnerability.

What Are the Different Types of Packing Tape Available?

Choosing the right packing tape can significantly impact the safety and presentation of your packages.

There are various types of packing tape, each designed for specific packaging needs. From standard clear tapes to specialized reinforced options, understanding the differences can help you select the best tape for your requirements.

When it comes to packing tape, variety is the spice of life. Standard clear packing tapes are versatile and widely used for everyday packaging tasks. They offer a good balance between strength and visibility, making them suitable for most shipping needs.

For heavier packages, reinforced tapes come into play. These tapes often feature stronger adhesives and additional backing materials, providing extra support for bulky or fragile items. Additionally, eco-friendly options are available for those looking to minimize their environmental impact without compromising on quality.

Specialty Tapes

| Type | Description | Best For |

|---|---|---|

| Double-Sided Tape | Adhesive on both sides for mounting and crafting | Decorative projects, mounting |

| Colored Tape | Available in various colors | Branding, color-coding |

| Filament Tape | Reinforced with fiberglass strands | Heavy-duty packaging |

| Eco-Friendly Tape | Made from recyclable or biodegradable materials | Sustainable packaging |

Selecting the right type of tape depends on your specific packaging needs. For example, filament tape is excellent for securing heavy boxes, while colored tape can enhance your branding efforts by allowing you to incorporate your company’s colors into the packaging.

Moreover, advancements in tape technology have led to the development of tapes that are easier to tear, reducing the frustration of struggling with stiff or brittle tapes. This not only improves efficiency but also enhances the overall packaging experience.

By understanding the different types of packing tape available, you can make informed decisions that align with your packaging goals, whether it’s ensuring maximum security, promoting your brand, or embracing sustainability.

Conclusion

Selecting the right packing tape is more than just choosing a sticky strip. It’s about ensuring quality, durability, and professionalism in every package

I added the link to “pressure-sensitive adhesive” because this term is fundamental in understanding how packing tape works. It explains why certain adhesives activate under pressure and are essential for tape functionality, making it a crucial keyword for readers seeking detailed information about adhesives. ↩

I linked to “tackifiers” because this component plays a key role in increasing the stickiness and bond strength of adhesives in packing tape. Understanding its function helps users recognize why quality tape requires this ingredient, improving the overall user experience. ↩

I linked to “plasticizers” as they improve flexibility and prevent brittleness, which is crucial for the performance of packing tape. Readers may want to learn about how this chemical compound contributes to making the tape more durable and adaptable under various conditions. ↩

I added the link to “film” because the type of film used can significantly affect the tape’s transparency and color appearance. Understanding the film’s impact helps users make better choices when selecting packing tape for various needs. ↩

I linked to “adhesive” because the adhesive composition is a major factor in determining the tape’s color. Lighter colors usually indicate higher-quality adhesives, which is important for users who prioritize premium packing materials. ↩

I linked to “transparency” because clear tape allows for easy visibility of the package contents and branding, which can be essential for businesses that want their packages to be both functional and visually appealing. ↩

I linked to “color significance” because the color of packing tape plays a crucial role in branding and visual appeal. Different colors can evoke different psychological responses, making it an important consideration in packaging design. ↩

I added the link to “Color Inspection” because the color of the packing tape is an important indicator of its quality. Lighter colors often signify higher purity and quality adhesives, so this step helps users assess the tape’s suitability for packaging. ↩

I linked to “Scent Check” because the scent of packing tape can be an important factor in determining its quality. High-quality tapes should have a neutral or mild smell, which ensures they are free from harsh chemicals. ↩

I linked to “Tension Test” because this test is one of the most effective ways to evaluate the strength and reliability of packing tape. A tape that stretches too easily may be of lower quality, so this method ensures the tape is durable. ↩

I added the link to “Thickness Measurement” because the thickness of the tape is a key factor that affects both its durability and performance. Users need to understand how to choose the right thickness based on their packaging needs. ↩

I linked to “Wrapping Tightness” because this ensures the tape is applied correctly, without bubbles or impurities, which can affect the overall quality and performance of the packaging tape. ↩

Evelyn

Customer Success Manager

Hi! I’m Evelyn from Hipack. .

I’m passionate about creating high-quality, custom packaging that makes your brand stand out. I’ve worked with luxury brands and jewelry distributors worldwide to deliver packaging that’s not only beautiful but also functional. Let’s dive in!

Send Us A Message

Share:

More Posts

Innovative Mooncake Packaging Box with Pantone Color Trends

Transform your mooncake packaging into a display stand with HiPack’s innovative design! Collaborating with a food company, we used the latest Pantone color trends to create a vibrant and versatile packaging solution.

Cartier’s 3D Promotional Cards with Voice Recording

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

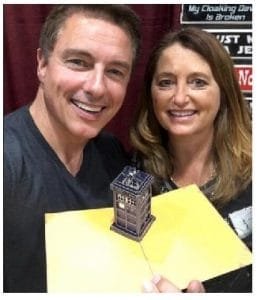

Custom 3D Popup Cards for BBC’s Sci-Fi Series “Doctor Who”

HiPack created custom 3D popup cards for BBC’s “Doctor Who,” featuring the iconic police box.

HiPack utilized laser cutting for precision and upgraded printing technology for vibrant images. The result is high-quality, collectible cards that capture the essence of “Doctor Who.”

High-Cost Specialty Paper for Italian Export Project

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.