HiPack’s Solutions for Clean, Durable Packaging

When it comes to packaging, the details matter. A well-designed package isn’t just a box; it’s your brand’s first impression. Whether you’re selling jewelry, gifts, or luxury goods, your packaging speaks volumes about your business. Let’s dive into how you can improve custom packaging1 for better brand presentation.

Packaging is more than just a functional item; it’s a powerful marketing tool that sets your product apart. From choosing the right colors and logos to mastering finishes like hot stamping2, every decision counts. Whether you’re improving your brand presentation or just making your products shine, the key is in the details.

Let’s break down the crucial elements of packaging that will elevate your brand.

How to Fix Common Logo and Color Issues in Packaging

The logo placement and color choice on your packaging are like the first handshake your brand has with customers. But what happens if they’re off? Let’s talk about how to fix that.

Logo placement and color choice can make or break your packaging. If your logo isn’t aligned properly or your colors don’t pop, your packaging could lose its effectiveness. Don’t worry though—fixing these issues isn’t as hard as it sounds.

Getting your logo placement and color choice right is essential for brand recognition. If your logo isn’t printed clearly or the colors aren’t exactly what you envisioned, it’s easy for your packaging to fall flat.

Logo Alignment and Size

Make sure your logo placement3 is well-positioned and visible from all angles. It’s important to test how it looks on different types of boxes or bags. Don’t let it get lost in the design, but also avoid overwhelming the design by making it too large.

Choosing the Right Colors

Color choice4 plays a huge role in how your brand is perceived. Think about your target audience: what do your colors say about your brand? If your colors clash or don’t reflect your brand identity, it can confuse your customers. Use colors that match your brand’s story—whether it’s luxury, eco-friendly, or playful.

Testing & Feedback

One of the best ways to fix logo placement and color choice issues is to ask for feedback. Before you print a massive run of packaging, test it with a small batch and get input from your target audience. You’ll be surprised how much this helps in improving your overall design.

The Importance of Hot Stamping: Tips for Achieving the Perfect Effect

Hot stamping can elevate your packaging to a whole new level. Let’s explore why this finishing technique is so important and how to get it just right.

Hot stamping adds a touch of luxury that sets your product apart. It’s not just about looks—it’s about creating an experience that your customers will remember.

Hot stamping isn’t just for fancy occasions—it’s a technique that can make your packaging look upscale and polished.

What is Hot Stamping?

It’s a printing process where metallic foil5 is applied to your packaging, creating a shiny, reflective finish. It’s perfect for logos, brand names, or decorative elements that need to stand out.

Why It’s Important

Hot stamping gives your packaging a high-end, luxurious feel. It makes even simple designs look sophisticated and premium. Plus, it creates a tactile experience6 that draws customers in.

Achieving the Perfect Effect

To get the best hot stamping result, make sure your design is simple, and avoid too much detail. Too many fine lines or small text can blur during the stamping process. Choose high-quality foils and always test before mass production.

Why Surface Finish Matters: Comparing Matte and Glossy Packaging

The surface finish of your packaging affects not only how it looks but how it feels. Let’s compare matte finish7 and glossy finish8 finishes and find out which one works best for your brand.

The choice between matte finish and glossy finish finishes might seem small, but it can have a huge impact on your brand’s presentation. Here’s how to make the right decision.

Choosing between matte finish and glossy finish isn’t just about preference—it’s about matching the finish to your brand’s personality.

Matte Finish

A matte finish gives a soft, sophisticated feel. It’s often used for high-end products, giving them a modern, minimalistic look. If you’re aiming for a premium or eco-friendly image, matte might be the best choice.

Glossy Finish

On the other hand, a glossy finish is shiny and bold. It reflects light, making colors pop and creating a more dynamic look. If you want your packaging to catch the eye and stand out on a shelf, glossy might be the way to go.

Which One to Choose?

It all depends on your brand’s voice. For a luxury brand, matte finish is often the go-to for a more subtle, refined look. For a fun, vibrant product, glossy finish may be the best choice. And don’t forget to consider how the finish interacts with other elements, like hot stamping or embossing.

How Production Methods Can Affect the Quality of Your Packaging

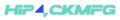

When it comes to custom packaging, the production method9 you choose can significantly affect the final quality. A common issue we’ve faced with paper bags is the appearance of clumps of fluff on the surface. These aren’t stains or dirt, but they can create a less-than-ideal first impression—especially for luxury products. So why does this happen, and how do we tackle the problem head-on?

The fluff you see on paper bags often comes from inconsistencies during the lamination process, especially when using black-colored glue. Here’s how we solved this problem by improving the production method to give a cleaner, more polished finish.

In our earlier method, we used black-colored glue applied through lamination process10. The challenge with this approach was that the thickness of the glue could vary, leading to color inconsistencies and uneven surfaces. As a result, the final product sometimes had a slightly messy or unpolished look—something no brand wants, especially when presenting luxury products.

Why Does the Fluff Appear?

The appearance of fluff on the paper surface is often due to an uneven application of glue, which doesn’t fully bond to the paper. This can cause tiny fibers or particles to stick to the surface, creating a rough texture or unwanted marks.

How We Tackled the Issue

Our solution was to move away from using glue and instead implement 100% black base printing. This allowed us to have consistent, high-quality printing without the risk of uneven glue application. Additionally, we upgraded the lamination process, opting for a more refined technique that guarantees an even finish.

Choosing the Right Materials

We also invested in higher-quality paper11 and laminate materials. The upgraded materials made the difference in terms of appearance and durability. The matte finish added sophistication, ensuring the bags looked professional from every angle.

Cost-Saving Packaging Techniques vs. Quality Standards: Finding the Right Balance

Balancing cost12 and quality13 is crucial in packaging. Let’s talk about how you can save on packaging costs without sacrificing quality.

When it comes to packaging, finding the right balance between cost and quality can be tricky. But with the right techniques, you can save money without cutting corners.

We all want to save money, but not at the expense of quality. Fortunately, there are ways to optimize your packaging without compromising on the final product.

Efficient Materials

Choosing the right efficient materials14 can save you a lot in the long run. For example, switching from custom-sized boxes15 to standard sizes might lower costs without compromising on the look.

Streamlined Production

One way to save on production is to streamline your processes16. Using fewer colors, simplifying your design, or opting for less complex printing techniques can help reduce costs while maintaining high quality.

Smart Outsourcing

Consider outsourcing17 some of your packaging components, like printing or assembly, to companies that specialize in these areas. This can cut costs while ensuring your packaging meets your quality standards.

Conclusion

Packaging isn’t just about keeping your product safe; it’s about creating a lasting impression. With the right approach, your custom packaging can be a game-changer for your brand’s presentation. Take the time to fine-tune each element, from colors to finishes, and watch your packaging elevate your business.

I linked to custom packaging because it is central to the article, and readers can benefit from learning about best practices to enhance their packaging strategies. ↩

I linked to hot stamping to provide more details on this finishing technique and how it contributes to creating a premium look and feel. ↩

I linked to logo placement to help readers understand how positioning their logos can impact brand recognition and packaging effectiveness. ↩

I linked to color choice to offer insights into selecting colors that align with brand identity and appeal to target audiences. ↩

I linked to metallic foil to explain this material and its role in adding reflective and luxurious elements to packaging. ↩

I linked to tactile experience to delve into how the feel of packaging can enhance customer engagement and satisfaction. ↩

I linked to matte finish to discuss its aesthetic and tactile benefits for high-end product presentation. ↩

I linked to glossy finish to explain how this finish can make packaging stand out and attract attention. ↩

I linked to production method to provide information on how choosing the right methods can influence packaging quality. ↩

I linked to lamination process to offer more details on this technique and its role in enhancing packaging quality. ↩

I linked to higher-quality paper to explain its impact on the overall look, feel, and durability of packaging. ↩

I linked to cost to help readers understand strategies to manage packaging expenses without compromising quality. ↩

I linked to quality to discuss essential standards that ensure packaging meets luxury market expectations. ↩

I linked to efficient materials to provide insights into materials that can reduce costs while maintaining packaging quality. ↩

I linked to custom-sized boxes to explain how choosing standard sizes can optimize costs without sacrificing aesthetics. ↩

I linked to streamline your processes to inform readers about methods to simplify production and reduce expenses. ↩

I linked to outsourcing to illustrate how delegating certain packaging tasks can enhance efficiency and quality. ↩

Evelyn

Customer Success Manager

Hi! I’m Evelyn from Hipack. .

I’m passionate about creating high-quality, custom packaging that makes your brand stand out. I’ve worked with luxury brands and jewelry distributors worldwide to deliver packaging that’s not only beautiful but also functional. Let’s dive in!

Send Us A Message

Share:

More Posts

Innovative Mooncake Packaging Box with Pantone Color Trends

Transform your mooncake packaging into a display stand with HiPack’s innovative design! Collaborating with a food company, we used the latest Pantone color trends to create a vibrant and versatile packaging solution.

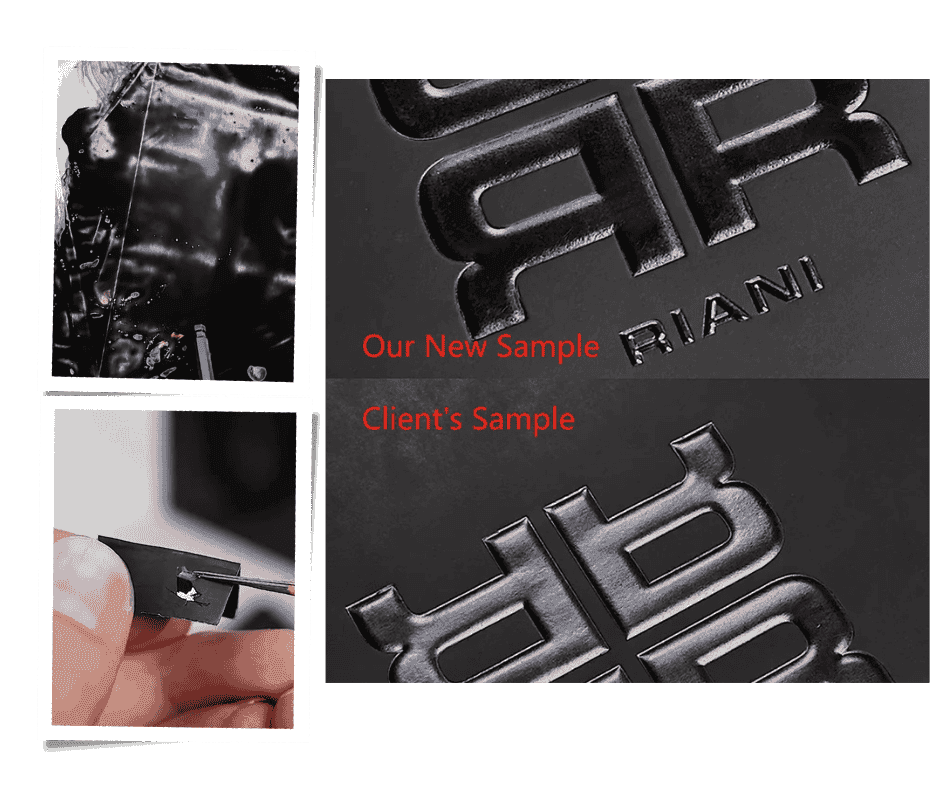

Cartier’s 3D Promotional Cards with Voice Recording

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

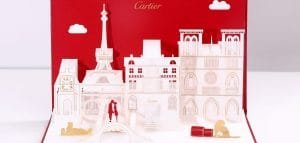

Custom 3D Popup Cards for BBC’s Sci-Fi Series “Doctor Who”

HiPack created custom 3D popup cards for BBC’s “Doctor Who,” featuring the iconic police box.

HiPack utilized laser cutting for precision and upgraded printing technology for vibrant images. The result is high-quality, collectible cards that capture the essence of “Doctor Who.”

High-Cost Specialty Paper for Italian Export Project

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.