Custom Gift Box Manufacturer in China | HiPack

Luxury & Eco-friendly

Custom Gift Boxes

from 500 Units

Better Prices

World manufacturing centres, lower production costs.

Rapid production

20-35 days, from order confirmation to production completion.

Quality Assurance

Strict production in accordance with ISO standards.

Customize your Gift Box with logo

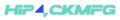

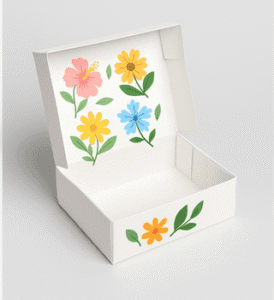

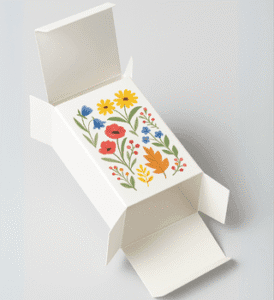

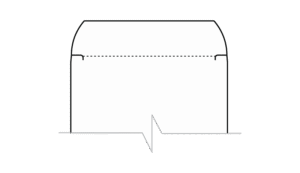

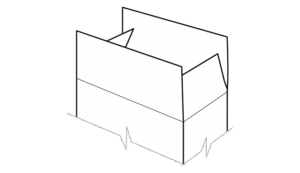

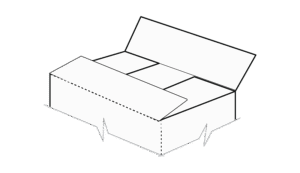

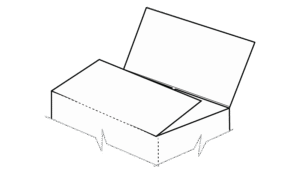

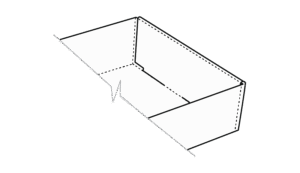

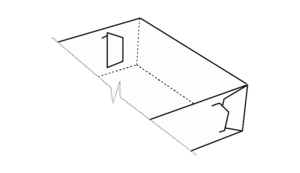

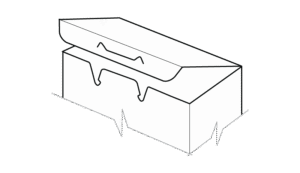

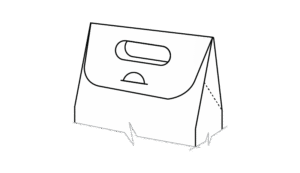

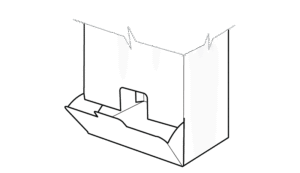

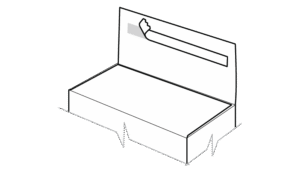

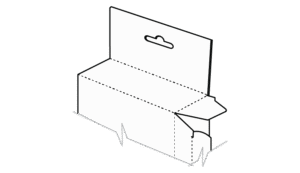

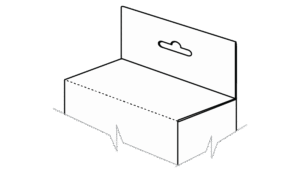

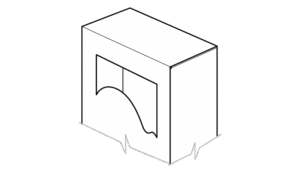

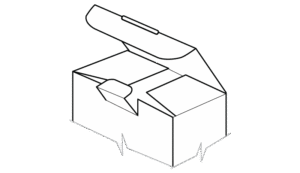

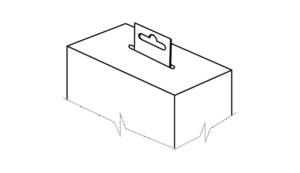

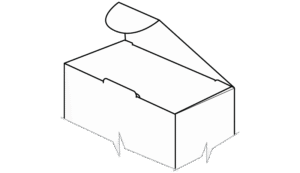

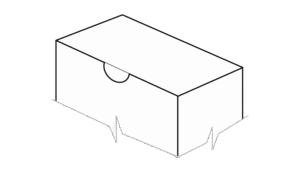

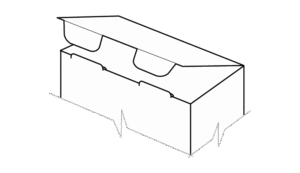

Don’t have design drawings? Maybe you will like these designs!

Easy 4-Step Ordering Process

Have an idea in mind? We help you bring your design drawings to life!

1. Tell Us What You Need

Share your box purpose, quantity, and any design ideas. No design? Our in-house team will help.

2. Get a Quote & Sample

Receive a custom solution and quotation within 24 hours. Sample can be made before production.

3. Confirm & Produce

Once approved, we begin mass production. You’ll get progress updates at each key stage.

4. Delivery & Support

We pack, ship, and notify you before dispatch. Ongoing support available after delivery.

What can you get

Customizing your greeting cards can be easy. Leave it all to hipackmfg.

High Production Capacity

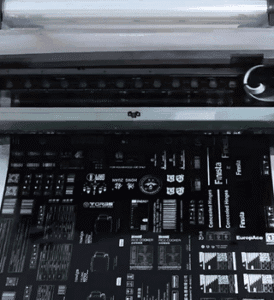

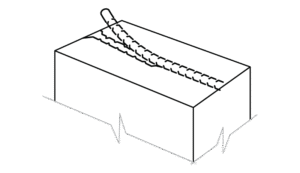

Equipped with state-of-the-art machinery, including the FORGA39 CMYK press and models like 15T, 15J, 5J, and 80T, we ensure precision and efficiency. With two modern factories located in Jiangsu and Zhejiang provinces, our skilled team provides tailored services from design to production, meeting diverse industry needs. Built on innovation and excellence, HipackMFG offers dependable solutions, fostering trust and security for clients worldwide.

Advanced Equipment

Our facilities are equipped with state-of-the-art machinery, including Heidelberg printing presses and Swiss automatic wood-grain lamination lines. These advanced technologies guarantee high-quality printing and finishing, ensuring your packaging stands out in the market.

Low MOQ

We offer flexible ordering options with a low MOQ starting from 100 units. This flexibility allows you to test new designs or cater to seasonal demands without the burden of large inventory commitments.

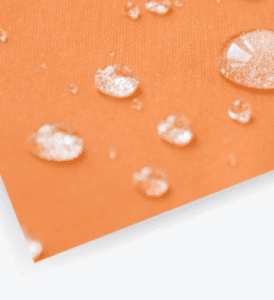

Commitment to Sustainability

HiPackMFG is dedicated to environmental responsibility. We utilize water-based inks, and eco-friendly finishes. By choosing our sustainable packaging solutions, you align your brand with eco-conscious practices, appealing to environmentally aware consumers.

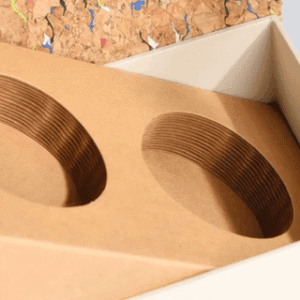

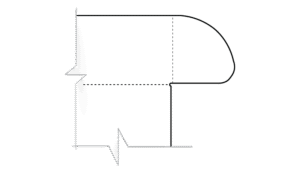

Structural Design & Sampling

We turn your ideas into professional structures with CAD & 3D renderings. No design? Our in-house team will handle it. Samples ready within 48h—get ahead of your competitors.

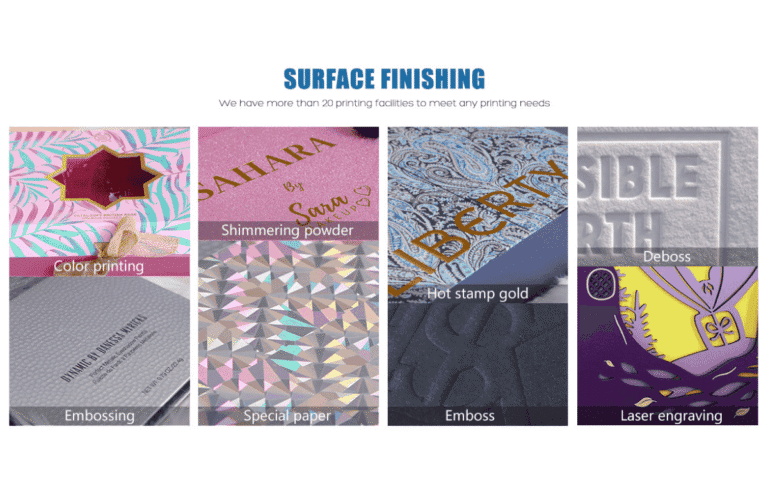

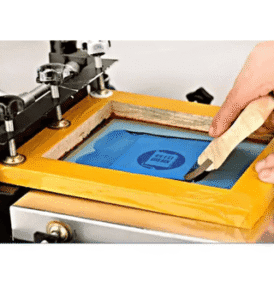

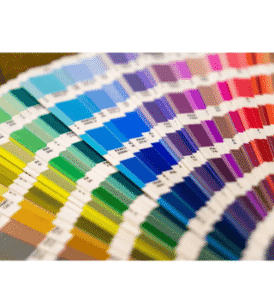

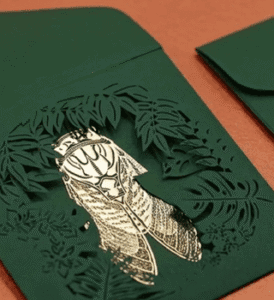

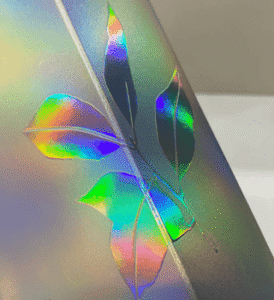

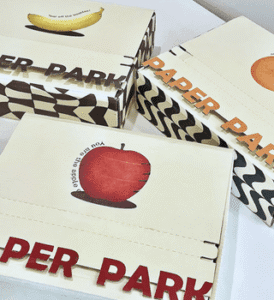

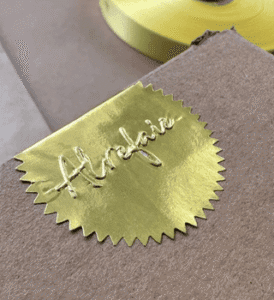

Printing & Finishing

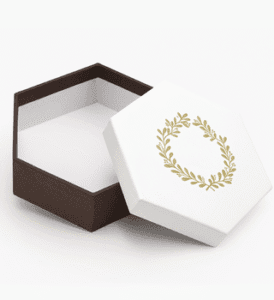

Stand out with foil stamping, embossing, or soft-touch finishes. These premium looks help you win shelf space and justify a higher retail price.

Flexible Assembly & Manual QC

Not fully automated—but that’s our strength. We combine semi-automation with skilled hand assembly, ensuring detail control for custom shapes and delicate finishes. Each box is manually inspected for quality.

Smart Packing & Global Delivery

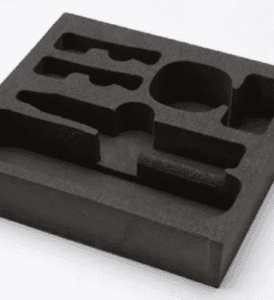

We provide custom inserts, kitting, and carbon-neutral shipping if needed. You get regular production updates and pre-shipment notice—no surprises.

Send The gift box Plan

Start Your Customized Project

Manufacturing Your Custom Packaging, Sustainably and Flexibly

Factory Insights

Whether you're in luxury jewelry, high-end cosmetics, or any other premium market, we've got you covered.

20+ Years Factory

The Power of Two Factories, the Flexibility of One Partner.

Industry Applications

customers Testimonials

Recognized by our clients around the globe.

Your trusted custom cards supplier | manufacturer in China.

As Senior Buyer at Elite Gifts Supply, I value suppliers who deliver quality and consistency. The Porsche gift boxes had flawless embossing, premium feel, and secure closures. Regular updates and professional service made our order worry-free. This factory has truly earned our trust for future business.

David Lee, Elite Gifts Supply

Our collaboration with this team was smooth and productive. The MARZANO gift boxes featured perfect logo alignment, clean finishing, and sturdy materials. Communication was always prompt and helpful, making the process stress-free. Their dedication to detail gives us confidence for long-term cooperation.

Luca, Brand Director, Italia

As Purchasing Manager at NewTrend Media, I was impressed by the factory’s fast response and attention to our custom requirements. The TikTok gift boxes arrived on time, with clear printing and strong build. The whole experience—from sampling to delivery—was efficient and reliable. We look forward to more projects together.

Emily Wang, China

Reach us

- We will contact within 12 hours.

- Don't worry, we hate spam too!

FAQ

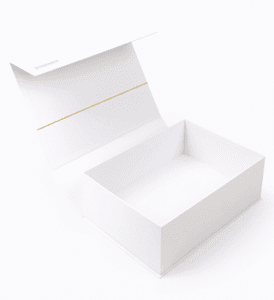

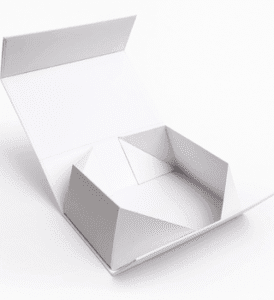

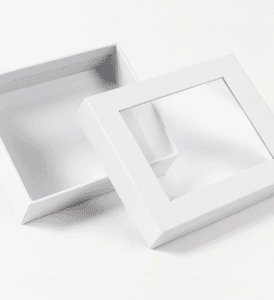

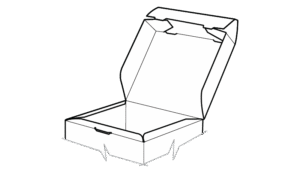

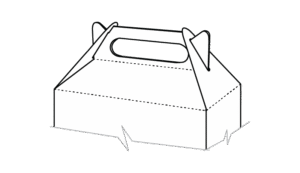

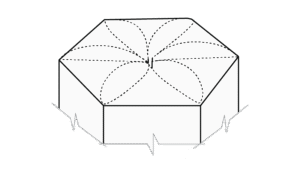

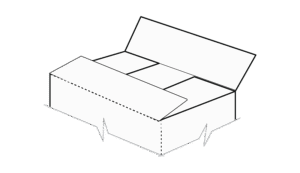

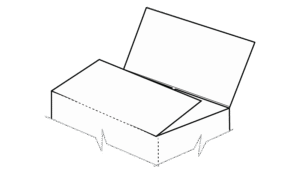

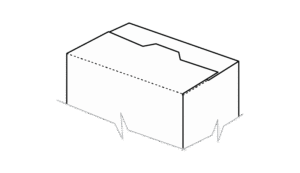

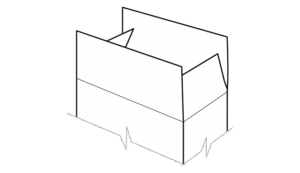

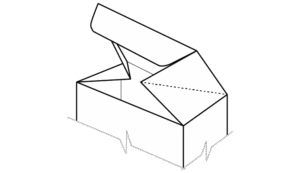

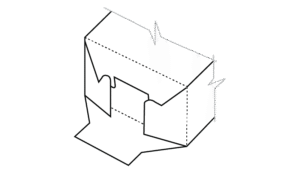

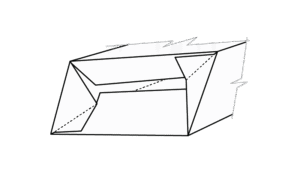

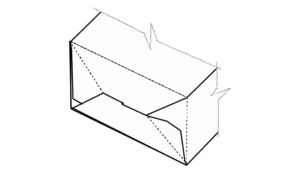

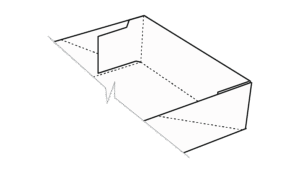

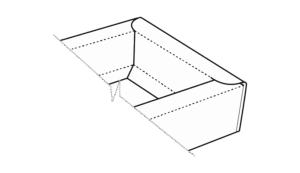

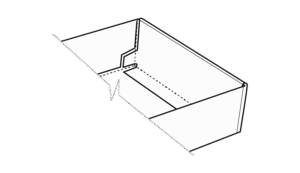

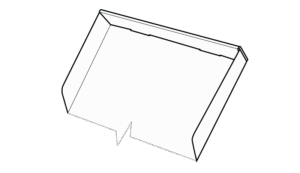

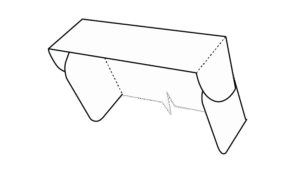

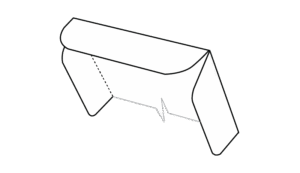

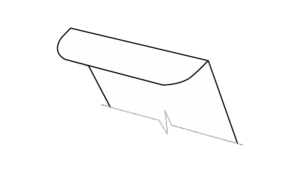

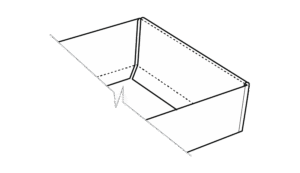

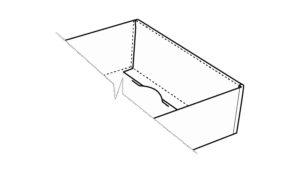

We produce a wide range of custom gift boxes, including rigid boxes, folding boxes, magnetic boxes, drawer boxes, and more. We support various shapes, sizes, and structures based on your needs.

Yes, we accept custom designs and can develop samples based on your drawings, references, or actual samples.

Our MOQ varies depending on the box type and design, but we offer low-MOQ options for first-time orders or sampling.

Absolutely. We provide physical samples for quality and structure checking. Custom samples are available, and some basic samples are free; shipping cost may apply.

We follow strict QC procedures from raw material to final packing. Each batch is inspected, and photos or videos can be shared for approval before shipment.

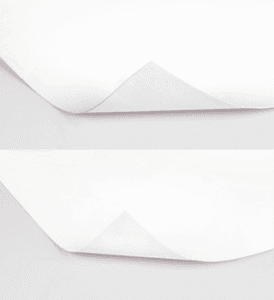

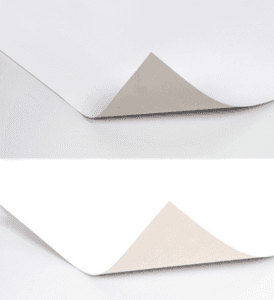

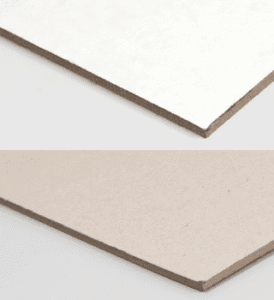

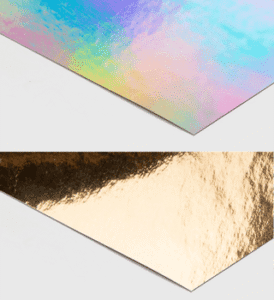

We offer various materials such as paperboard, greyboard, kraft, art paper, and specialty papers. Finishes include matte/glossy lamination, foil stamping, embossing, UV coating, and more.

Standard production time is usually 30 days after sample approval, depending on order quantity and box complexity.

Yes, we have an in-house design team to assist with dielines, artwork, and structure suggestions to achieve the best results.

We accept T/T, PayPal, and L/C for larger orders. Flexible payment terms are available for long-term partners.

Gift Box Materials & Customization Options

Craft the perfect packaging for your brand with our extensive range of materials, printing techniques, and finishing touches.

Folding Carton Boxes

Rigid Gift Boxes

Coatings

Lamination

Special Options

Decorate

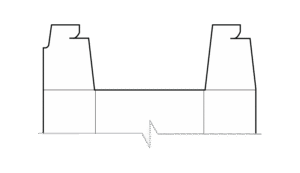

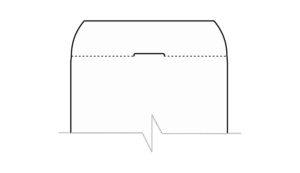

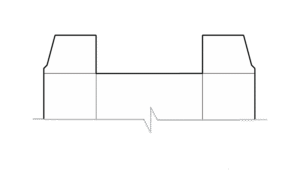

Top Closure

Bottom Closure

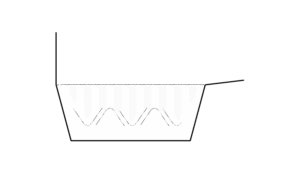

Tray & Lids

Other Features

Start Creating Now!

Get 100+ Free 3D Box Designs!

Drop Your Email – We’ll Send the Catalog in 24 Hours!