I remember the first time I laid my hands on a piece of specialty potato paper. It felt like holding a piece of art—fragile yet robust. At HiPack, we’ve always strived to push the boundaries of luxury packaging, and this material seemed like the perfect canvas.

Choosing the right material for luxury packaging isn’t just about looks; it’s about making a statement. At HiPack, we’ve embraced specialty potato paper to craft packaging that’s not only stunning but also eco-friendly. This journey hasn’t been easy, facing challenges in sourcing and production, but it’s been incredibly rewarding. We’ve discovered that this unique paper elevates our designs and resonates with clients who value both quality and sustainability.

Let me share how we navigated this journey and what we’ve learned along the way.

Sourcing Excellence: Choosing Specialty Potato Paper for Premium Packaging

Finding the perfect material for our luxury packaging was no small feat. Specialty potato paper caught our eye, but sourcing it was a journey in itself.

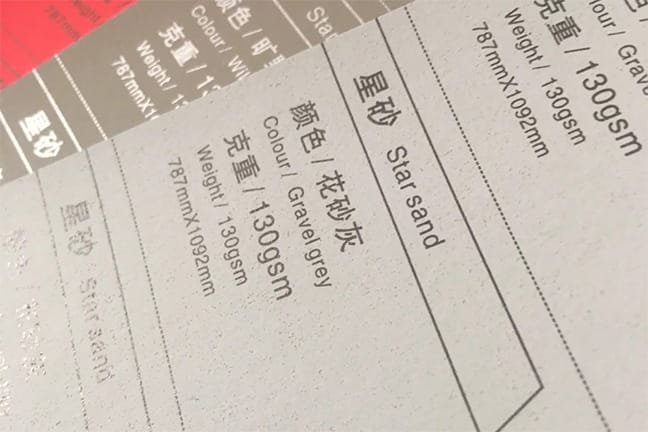

Specialty potato paper offers a unique blend of texture and sustainability, making it ideal for premium packaging. At HiPack, we chose this material to differentiate our products and align with eco-conscious values. Its natural fibers provide a luxurious feel that resonates with high-end consumers.

The Allure of Specialty Potato Paper

When I first heard about potato paper, I was intrigued—and a bit skeptical. Could paper made from potatoes really meet the standards of luxury packaging? As it turns out, not only does it meet those standards, it surpasses them.

The texture of specialty potato paper is unlike anything else. It has a subtle roughness that adds character, yet it’s smooth enough to feel premium. This balance is perfect for high-end brands looking to stand out.

Sourcing Challenges and Solutions

But sourcing this unique material wasn’t straightforward. The suppliers were few, and the costs were higher than traditional paper. We had to weigh the benefits against the expenses.

We conducted a cost-benefit analysis:

| Option | Kosten | Voordelen |

|---|

| Traditional Paper | Low | Familiar, readily available |

| Specialty Potato Paper | Hoog | Unique texture, eco-friendly, premium feel |

In the end, the potential to offer something truly different won us over.

Aligning with Sustainability

More and more, clients are valuing sustainability. By choosing potato paper, we’re not just offering a luxury product; we’re contributing to environmental responsibility. This resonates with both brands and consumers who prioritize eco-friendly practices.

Overcoming Production Hurdles: From Cost Challenges to Quality Assurance

Embracing new materials brought its own set of challenges. From managing costs to ensuring consistent quality, we had our work cut out for us.

Overcoming production hurdles with specialty potato paper involved addressing higher material costs and stringent quality control. At HiPack, we optimized our processes to balance expenses without compromising on quality, ensuring that our premium packaging meets the highest standards.

One of the first hurdles we faced was the increased cost of potato paper compared to conventional materials. We knew that to offer competitive pricing to clients like Mark Chen, who are sensitive to both quality and price, we had to find efficiencies elsewhere.

Streamlining Production Processes

We analyzed every step of our production line, identifying areas where we could reduce waste and improve efficiency. By investing in advanced machinery and training our staff, we managed to lower operational costs.

Bulk Purchasing and Negotiations

We also negotiated with suppliers for bulk purchasing discounts. Building strong relationships with our suppliers allowed us to secure better pricing, which we could then pass on to our clients.

Quality is non-negotiable in luxury packaging. We implemented rigorous quality control measures:

- Material Inspection: Each batch of potato paper is inspected for consistency in texture and color.

- Production Monitoring: Our production lines are monitored in real-time to catch any deviations immediately.

- Final Product Testing: Before shipping, we conduct stress tests to ensure durability.

By overcoming these hurdles, we’ve been able to deliver high-quality, premium packaging without significant cost increases to our clients.

Innovative Design Solutions: Magnetic Closures and M shaped Japanese Bottom of Handbag

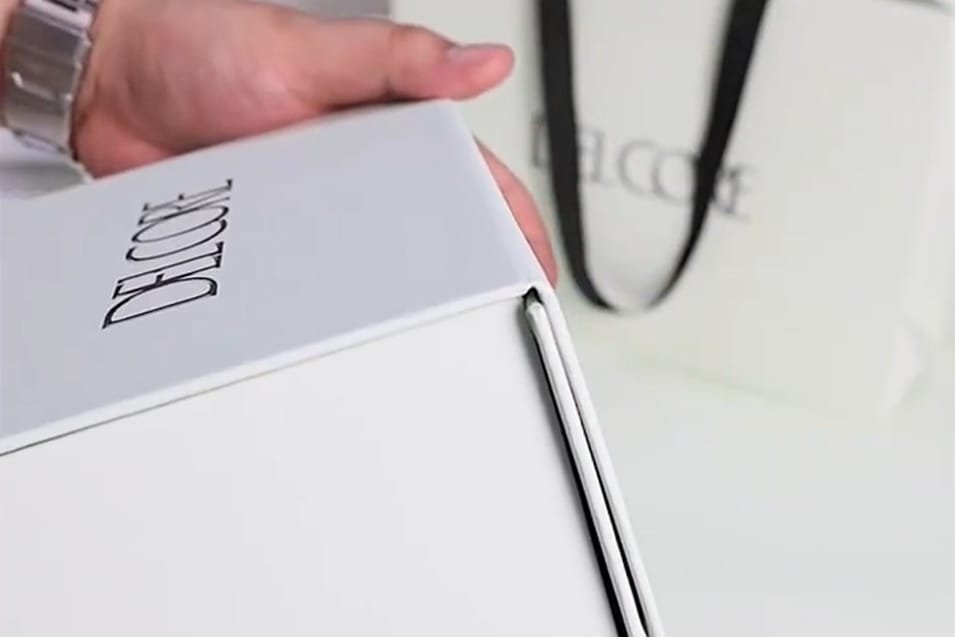

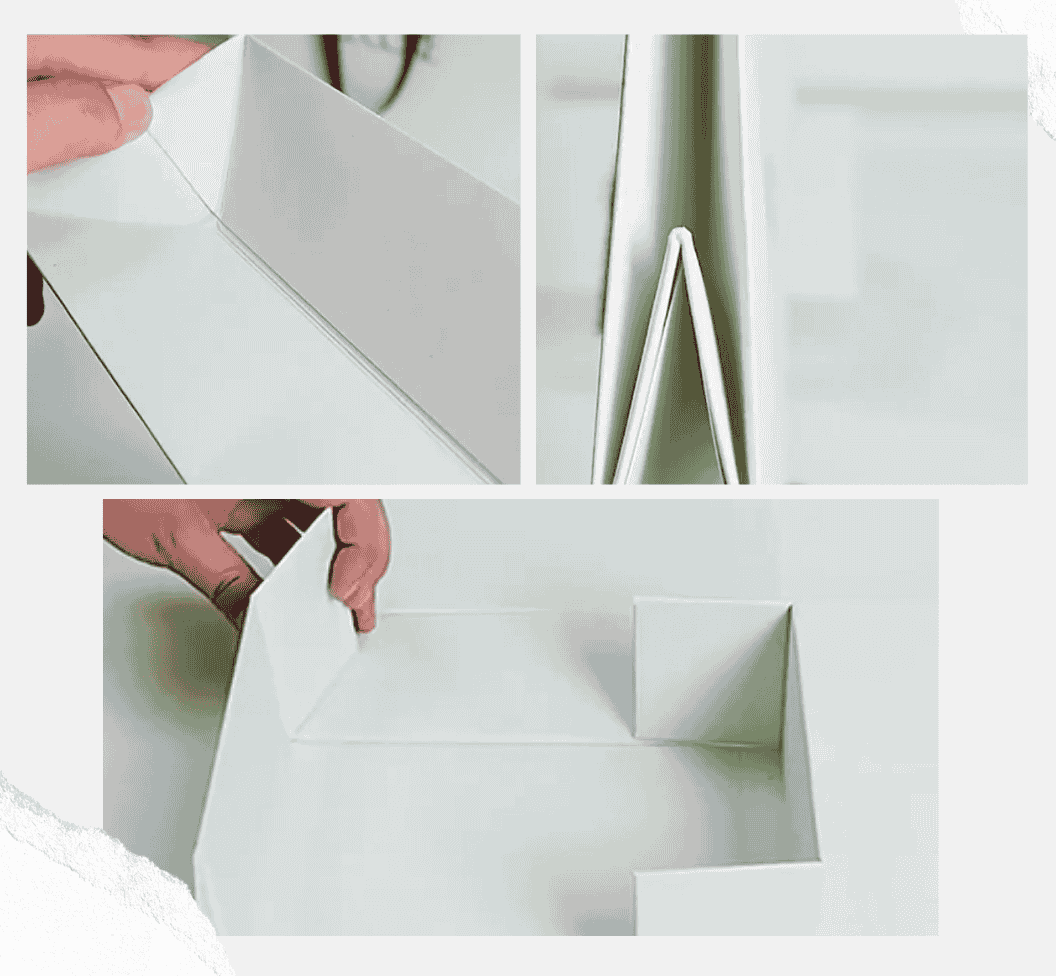

Packaging isn’t just about protecting the product inside—it’s about creating an experience for the customer. That’s why we’re always looking for innovative solutions to add an extra layer of elegance and functionality. One of our standout features? Magnetic closures and the Japanese bottom of a handbag.

Magnetic closures add that extra “wow” factor, making the unboxing experience feel exclusive. Combined with the sleek, sophisticated Japanese bottom design, it creates packaging that feels as luxurious as the product itself.

The Magic of Magnetic Closures

There’s something satisfying about the subtle ‘click’ of a magnetic closure. It signals quality and attention to detail. We decided to integrate magnetic closures into our designs to enhance both functionality and user experience.

Benefits of Magnetic Clos