In the world of modern printing, acrylic materials stand out for their versatility and stunning visual appeal. The images provided offer an insightful look into the meticulous process behind creating high-quality acrylic prints, highlighting the challenges and solutions involved.

Understanding the Acrylic Printing

Acrylic Printing Machine:

- The acrylic printing process requires high precision to ensure clarity and avoid blurriness. Therefore, the printing must be done slowly and carefully to achieve the best results.

Acrylic Sheet Material:

- Despite appearing straightforward, the production of these intricate designs is quite complex and demands detailed file preparation. The following explanation focuses on achieving the desired transparency effects.

Transparency and Color Effects:

- The different transparency levels and colors are crucial in acrylic printing. As shown, achieving various effects involves manipulating transparency levels ranging from 10% to 100%. This precision in transparency is vital for creating the detailed and vibrant patterns seen in the final product.

Transparency Effects:

The images show different transparency levels, such as 90% black, 50% transparent purple, and 40% transparent orange, among others. These effects are achieved by adjusting the printing process to ensure each color and transparency level is accurately represented.

Design Choices:

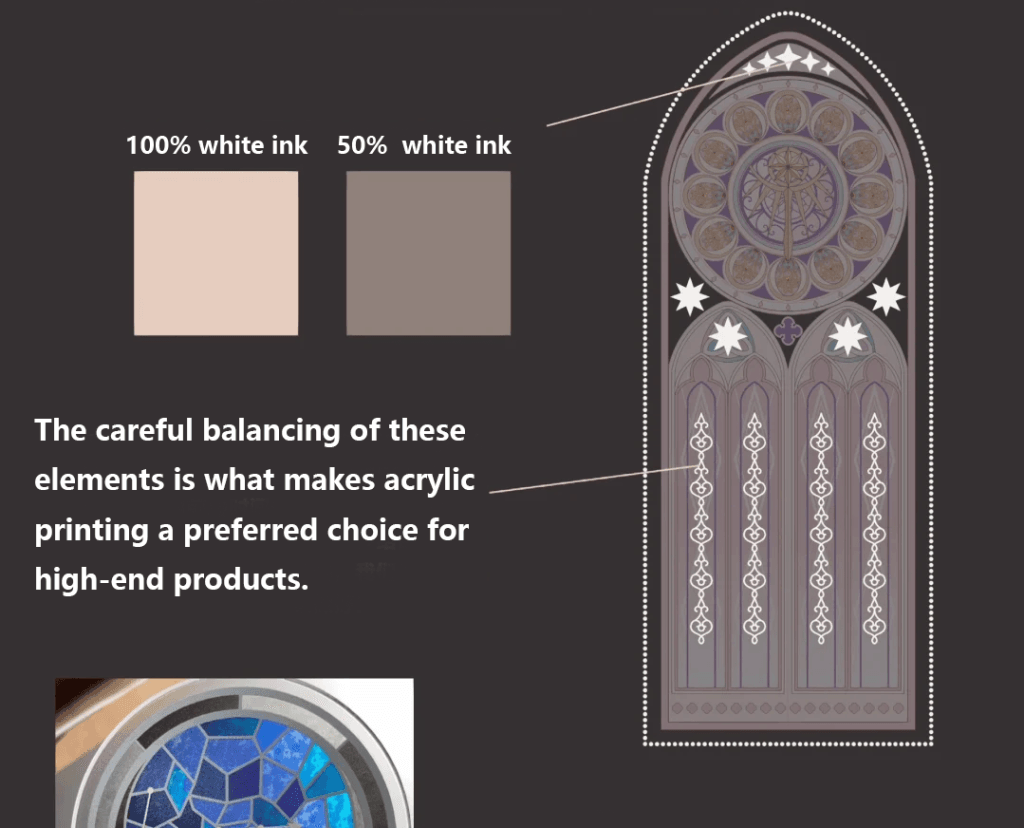

When designing for acrylic printing, one can choose to print the entire back of the design in white or partially, as shown in the illustrations. This choice affects how light passes through the acrylic, creating either a more opaque or a more translucent effect.

Layering and Depth:

Adding layers of white ink behind the main design can increase depth and detail. For example, using 100% white ink for certain parts and 50% for others can create a layered effect, enhancing the visual complexity and appeal of the print.

Challenges and Solutions in Acrylic Printing

- Precisiesnijden:

- Ensuring the laser cutting process is precise to match the design specifications without errors. This involves meticulous calibration and testing to achieve flawless cuts.

- Color Consistency:

- Achieving consistent and vibrant colors requires fine-tuning the printing settings. This ensures that the colors remain true to the design, without fading or inconsistencies.

- Transparency Management:

- Managing different transparency levels is crucial for creating the desired visual effects. This involves careful adjustment of printing parameters and thorough testing to ensure the final product meets the design expectations.

The detailed images provided offer a glimpse into the sophisticated process of acrylic printing. From managing transparency levels to ensuring precision in laser cutting, each step requires meticulous attention to detail. This ensures that the final product not only meets but exceeds expectations, showcasing the true potential of acrylic materials in modern printing.

By mastering these intricate techniques, HiPack continues to deliver high-quality, visually stunning acrylic products that stand out in any setting.