What Does ‘Perfect’ Mean for a 3D Popup Card?

- Popup Cards

Libby

CEO of HiPack.

Hi! I’m Libby from Hipack.

I’m passionate about creating high-quality, custom packaging that makes your brand stand out. I’ve worked with luxury brands and jewelry distributors worldwide to deliver packaging that’s not only beautiful but also functional. Let’s dive in!

Send Us A Message

Share:

More Posts

Innovative Mooncake Packaging Box with Pantone Color Trends

Transform your mooncake packaging into a display stand with HiPack’s innovative design! Collaborating with a food company, we used the latest Pantone color trends to create a vibrant and versatile packaging solution.

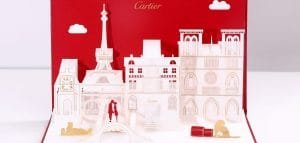

Cartier’s 3D Promotional Cards with Voice Recording

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

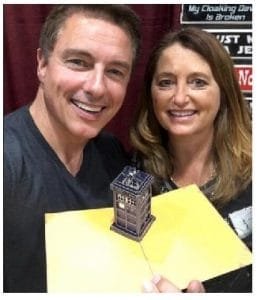

Custom 3D Popup Cards for BBC’s Sci-Fi Series “Doctor Who”

HiPack created custom 3D popup cards for BBC’s “Doctor Who,” featuring the iconic police box.

HiPack utilized laser cutting for precision and upgraded printing technology for vibrant images. The result is high-quality, collectible cards that capture the essence of “Doctor Who.”

High-Cost Specialty Paper for Italian Export Project

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

- By Evelyn

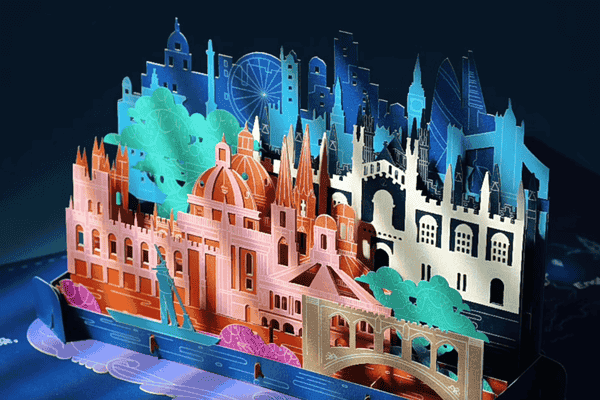

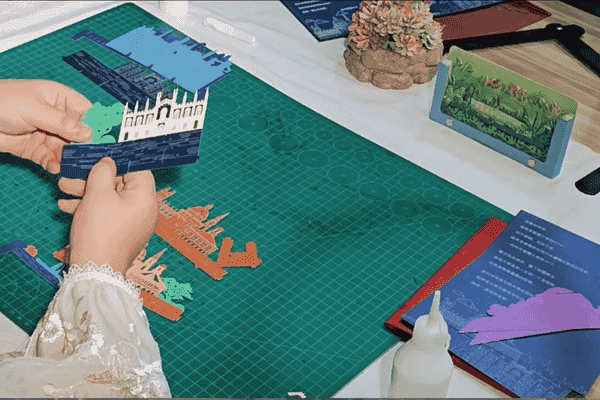

Hey there! I’m Libby from HiPack in China. Our 3D popup cards1 are little treasures, and I’m excited to share how we keep them perfect for your clients—every single time.

Our 3D popup cards must be spotless—no scratches, perfect printing2, tight assembly, and matching the sample exactly. It’s how we make your customers smile!**

Ready to peek behind the scenes? Let’s chat about what makes these cards special.

What does ‘perfect’ mean for a 3D popup card?

Hi! Perfection’s my obsession at HiPack. A card isn’t just paper—it’s a moment, and we check every detail to make it shine.

A perfect 3D popup card has no damage, crisp printing, snug assembly, and mirrors the sample. It’s built to impress your buyers!

Let me tell you about my first big moment with a card. It was for a jewelry buyer in Singapore. I held that card—smooth, no smudges, edges sharp—and I knew it had to be flawless. When they opened it, their gasp said it all. “Libby, it’s gorgeous!” That’s why we sweat the small stuff.

Here’s how we do it:

- Condition: No dents or creases. I run my fingers over every card—call it my personal test.

- Printing: Colors pop, no stray ink. It’s like painting a tiny masterpiece.

- Assembly: Everything clicks tight. A loose piece? No way—it’s gotta hold.

- Sample Match: It’s our promise. If it’s off, it’s not leaving my factory.

Why Bother?

One flaw—like a scratch—can ruin the magic. Imagine giving a gift that’s chipped. Ugh, right? But when it’s perfect, it’s joy in their hands. I’ve seen buyers in North America light up over a card that felt just right. It’s not just business; it’s trust.

Here’s a quick peek at our checklist:

| Check | What We Look For |

|---|---|

| Damage | No scratches or dents |

| Printing | Bright, clean, no spots |

| Assembly | Snug and sturdy |

| Sample Match | Identical every time |

It’s simple, but it works. What do you think—would your clients notice that care?

Why is printing such a big deal?

Printing’s the heartbeat of our cards. It’s not just ink—it’s the first hello your customer gets.

Printing needs perfect colors, no smudges, and sharp alignment. It’s what makes our 3D popup cards stand out!

I’ll never forget a Japanese buyer who wanted this exact shade of blue. Five tries—five!—and I was sweating. Finally, we nailed it. They bowed and said, “Libby-san, arigato.” That blue wasn’t just color; it was respect. Printing’s our handshake, and it’s gotta feel firm.

Here’s the breakdown:

- Color: We match it with charts—nerdy, but it works.

- Cleanliness: No ink blobs. Clean cards, happy hearts.

- Alignment: Straight as an arrow. Misaligned? It’s a no-go.

The Details Matter

I keep Pantone swatches by my desk. Silly? Maybe. But when a luxury buyer in Korea asks for gold foil, I’m ready. Ever matched a color so well it felt like a win? That’s me, grinning like a kid.

Printing’s where we show off. A smudge can dull the sparkle—imagine a jewel box with a faded lid. Nope! We tweak, test, and tweak again. Our five production lines hum to get it right. For big buyers—like jewelry distributors—it’s not just a card; it’s their brand shining through. How does your packaging say hello?

How do we keep the 3D parts solid?

Assembly’s the fun part—where flat paper turns into a tiny stage. It’s gotta be tight and right.

3D parts must be glued neatly, snapped tight, and match the sample. That’s how our cards come to life!

Picture this: I’m watching our team build a card with a mini Eiffel Tower. Click, click—perfect. Then one wobbled. My heart sank! We fixed it, and now we double-check every snap. That wobble taught me: solid assembly isn’t optional.

Here’s the magic:

- Gluing: Just enough—no mess.

- Snaps: Tight, no flops.

- Match: Sample’s the boss.

The Big Why

A loose bit ruins the show—like a puppet with cut strings. Sad, right? But when it’s snug, it’s a wow moment. I’ve seen a buyer in Japan unfold one and whisper, “Beautiful.” That’s the goal.

Our factory’s lines churn out thousands million, but each card gets a once-over. For luxury clients—like those jewelry folks—it’s gotta feel premium. Ever had a gift fall apart? Disappointing. We glue with precision, snap with care, and test like it’s for my own family.

| Step | How We Nail It |

|---|---|

| Gluing | Tiny drops, no spills |

| Snaps | Firm clicks, no wiggles |

| Sample Check | Side-by-side every time |

It’s hands-on, and I love it. What’s your favorite part of a popup card?

What happens if a card doesn’t match the sample?

The sample’s my guide—my North Star. If a card’s off, it’s not going anywhere.

Every card must match the sample—colors, feel, everything. If it doesn’t, we redo it. No exceptions!

A Korean luxury buyer once sent a sample with gold foil. One batch shifted—tiny, but they caught it. I blushed, apologized, and we added extra checks. Now, they trust us. Mistakes sting, but they make us better.

Here’s how we stick to it:

- Comparison: Sample and card, side by side.

- Details: Every texture, every hue.

- Client Wishes: Special requests? Done.

Trust in Every Fold

I tell my team, “Make it like it’s for your grandma.” Cheesy? Sure. But it’s love in action. A mismatch isn’t just a flaw—it’s a broken promise. We’ve built trust with buyers in Singapore, Japan, everywhere, by matching samples down to the dot.

Once, at an exhibition, a buyer held our card next to their sample—silence, then a nod. That nod? Gold. For big companies, it’s their logo, their story. We redo batches if we must. It’s not cheap, but trust isn’t either. Ever had a supplier let you down? I won’t be that one.

Conclusion

Hi! I’m Libby, and at HiPack, our 3D popup cards1 are made with care. Want to delight your clients? Email me at sales@hipackmfg.com or visit www.hipackmfg.com—let’s chat!